7

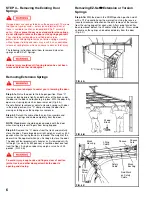

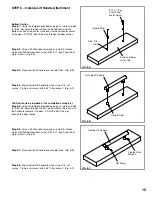

STEP 5 – Removing Door Sections and Track

Step 5-1:

The door can now be disassembled. Starting with the

top section, remove the hardware and unstack the sections one

at a time. (Fig. 5-A)

Step 5-2:

After all sections have been removed from the

opening, detach all remaining track and hardware from the

jambs. The hangers that attach the rear ends of the overhead

track to the ceiling (called rear track hangers) in many cases can

be reused on the new door if made of 13 gauge (3/32") or

heavier steel and is not loose or unstable. (Fig. 5-B)

To avoid installation problems which could result in

personal injury or property damage, use only the track

specified and supplied with the door. Do not attempt to

reuse old track

.

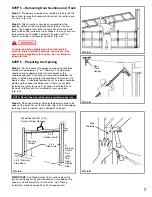

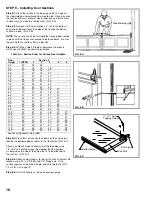

STEP 6 – Preparing the Opening

Step 6-1:

On the inside of the garage your opening should be

framed with wood jambs, 2" x 6" if possible. The side jambs

should extend to approximately the same height as the

headroom required. If you have just removed an old door, the

jambs should be inspected for the condition of the wood. If the

wood is rotten, it should be replaced now. The jambs should be

plumb and the header should be level. If there are any bolts

fastening the jambs to the wall, the heads should be flush so

they don’t interfere with the installation of your new door.

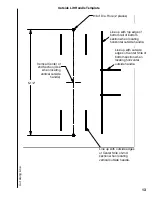

(Fig. 6-A)

NOTE: Rough Opening (without stop molding)=door size

Step 6-2:

Door stop molding should be temporarily nailed to the

edges of the jambs flush with the inside. (Fig. 6-B) Stop molding

featuring a built-in weather seal is offered as an option.

FIG. 6-A

*IMPORTANT:

The Wood Anchor Pad is used to mount the

torsion spring and has specific requirements for wood quality,

species, and attachment that must be met. See “Spring

Installation” section on page 23 or 26 for requirements.

FIG. 5-A

FIG. 5-B

FIG. 6-B

Wood Anchor Pad* (2 x 6)

Center of Door Opening

Rear

Track

Hanger

Stop

Molding

2 x 6

“Side Jamb”

8”

Minimum

Center

Post

(With

Two

Doors

Side by

Side)

3-3/4” Minimum

Side Room

2 x 6

“Header Jamb”

Opening

Height