19

Transaxle Disassembly, Inspection, and Assembly

TRANSAXLE (TYPE G)

TRANSAXLE DISASSEMBLY, INSPECTION, AND ASSEMBLY

See General Warnings on page 1-1.

TRANSAXLE DISASSEMBLY AND INSPECTION

1.

To detach axle tubes (14 and 35) from the transaxle housing, remove the bolts (8)

(Figure 19-5, Page 19-3)

.

2.

Remove 11 bolts (24) that hold housing together.

3.

Pull the halves of the housing (11 and 20) apart. If necessary, tap lightly on the spline of the input pinion (17).

See following CAUTION.

CAUTION

• To prevent damage to the housing mating seal surfaces, use caution when separating halves.

4.

Remove input pinion gear (17) by pulling gear out while rocking intermediate gear assembly (19). Lift intermediate

gear assembly and differential gear case unit out simultaneously

(Figure 19-5, Page 19-3)

.

See following

CAUTION.

CAUTION

• Do not damage gears. Use extreme care when handling them.

5.

Use a bearing puller or arbor press to remove bearings (16) from the input pinion gear. If the oil seal (10) is

damaged, replace it

(Figure 19-5, Page 19-3)

.

See also Figure 19-13, Page 19-8. See following CAUTION.

CAUTION

• Do not reuse bearings after removing them. Replace bearings with new ones.

6.

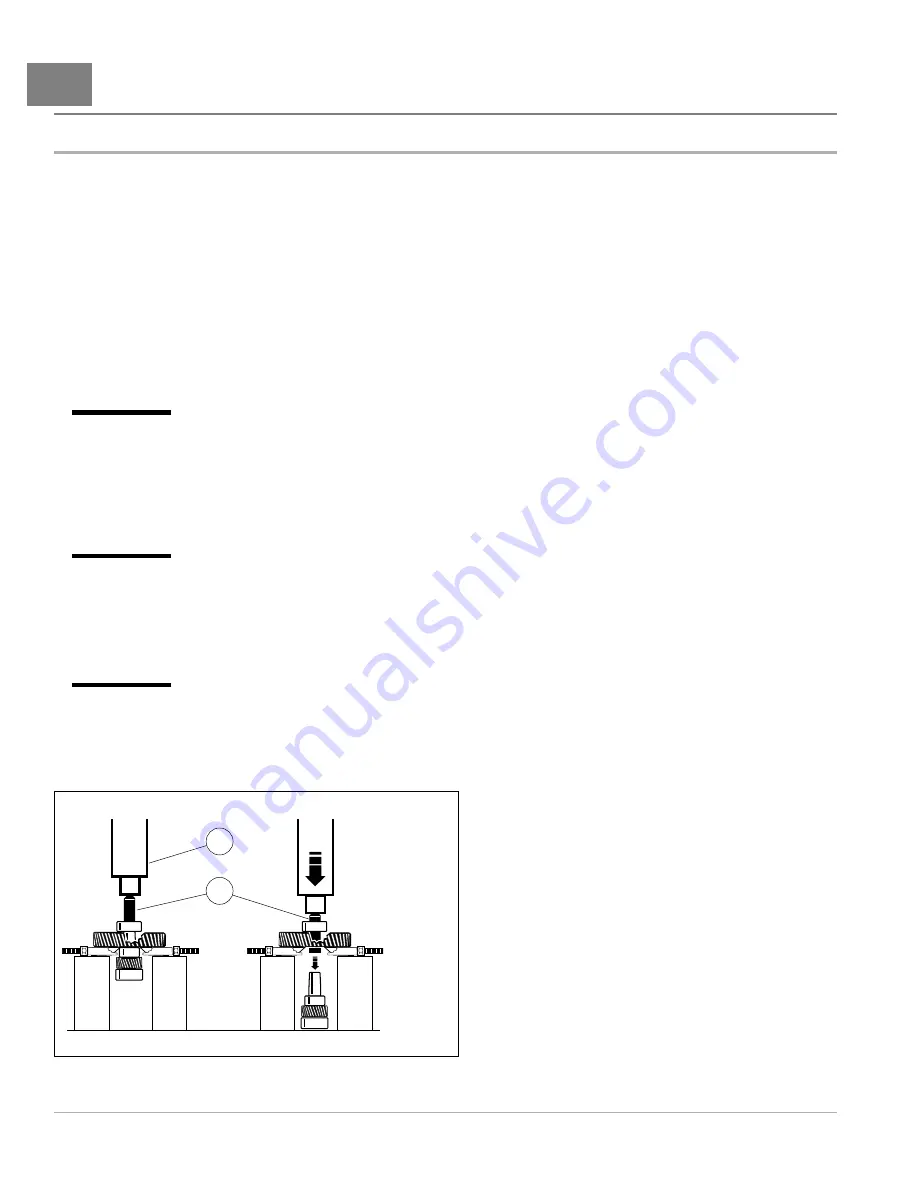

To disassemble the intermediate gear assembly, press off together the bearing (16) and the gear (19)

(Figure

19-5, Page 19-3)

.

See also Figure 19-13, Page 19-8.

7.

Press the bearing (18) off the intermediate gear assembly

(Figure 19-5, Page 19-3)

.

2

1

1. Press Ram 2. Arbor

771

Figure 19-13

Intermediate Gear Assembly

Page 19-8

2009 Electric Precedent Maintenance and Service Manual