GASOLINE ENGINE, MUFFLER, FUEL SYSTEM,

AND CLUTCHES

Clutches

15

CLUTCHES

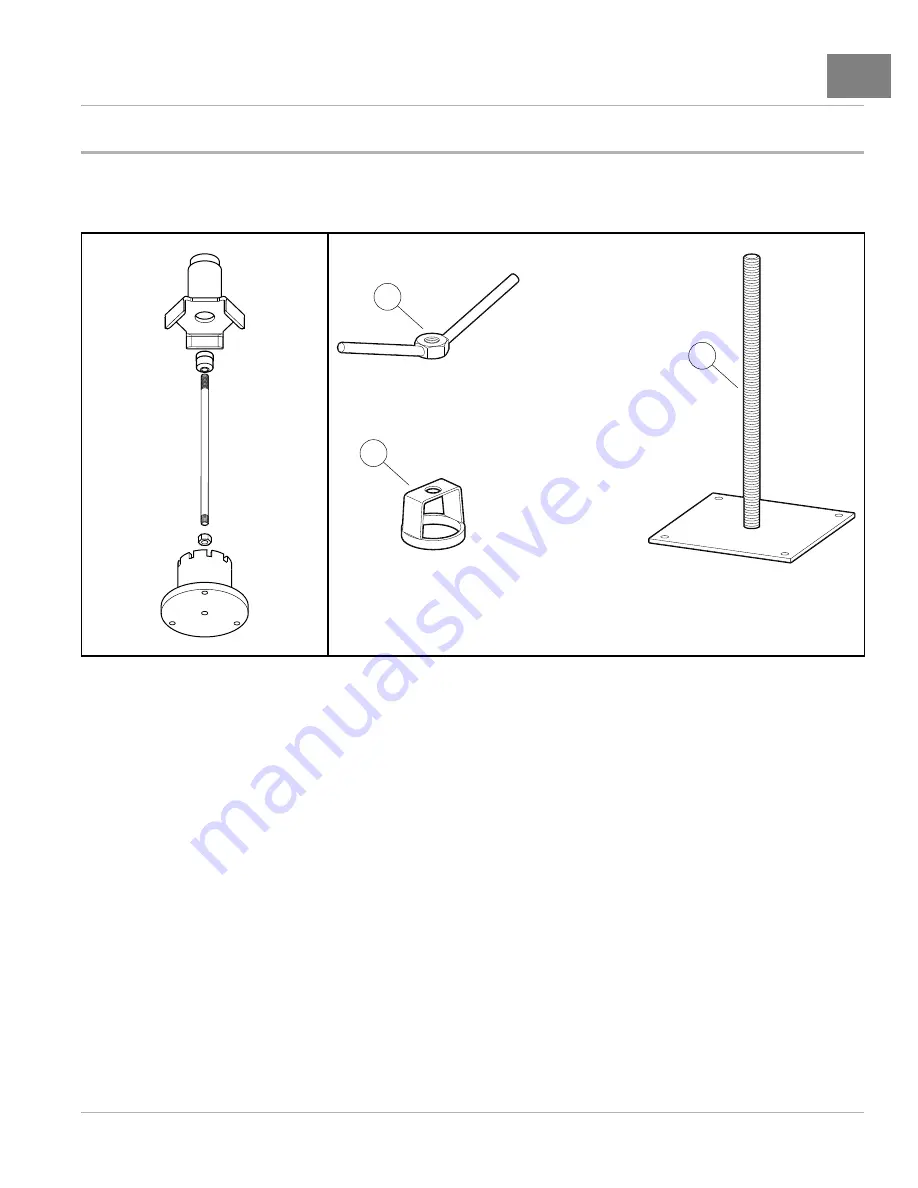

The following service tools are required to disassemble the clutches properly and are available from a service parts

representative

(Figure 15-24, Page 15-29) and (Figure 15-25, Page 15-29)

CC P/N 103865301

3

2

1

1. Spring compression nut (CC P/N 102606101) 2. Spring compression collar (CC P/N 102605201)

3. Spring compression base (CC P/N 102603501)

2498

Figure 15-24

Drive Clutch Service Tool – Three-Weight

Design

2499

Figure 15-25

Driven Clutch Service Tools

CLUTCH TROUBLESHOOTING

See General Warnings, Section 1, Page 1-2.

Use a tachometer during vehicle operation to determine if the engine begins to lose RPM when the vehicle climbs a

steep hill. Check the engine RPM and governor adjustments. If these adjustments are within specifications, there is a

clutch problem.

See Engine RPM Adjustment on page 15-25.

If the clutches are not operating properly, perform the following:

1.

Check the governor and throttle settings.

See Engine RPM Adjustment on page 15-25.

2.

Inspect both clutches for dirt and debris buildup on component parts. Clean the exterior surfaces of both clutches

with water to remove any dust or dirt, then drive the vehicle and check for proper operation.

page 15-30. See also Driven Clutch on page 15-34.

3.

Check the clean clutches for wear.

4.

If cleaning both clutches does not solve the problem, disassemble and thoroughly clean all parts in the drive

and driven clutches.

5.

Check the drive clutch rollers and weights for wear.

See Drive Clutch Cleaning and Inspection on page 15-31.

2016 Carryall 1500/1700 and XRT 1550 Maintenance and Service Manual

Page 15-29

Summary of Contents for Carryall 1500 2016

Page 2: ......

Page 432: ...NOTES...

Page 433: ...NOTES...

Page 434: ...NOTES...

Page 435: ......

Page 436: ......