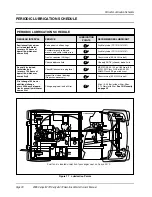

Periodic Lubrication Schedule

Page 30

2005 Carryall 272/ Carryall 472 Gasoline Vehicle Owner’s Manual

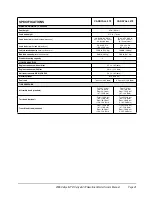

PERIODIC LUBRICATION SCHEDULE

PERIODIC LUBRICATION SCHEDULE

REGULAR INTERVAL

SERVICE

LUBRICATION

POINTS

RECOMMENDED LUBRICANT

Semiannually by owner

or trained technician

(or every 50 hours of

operation, whichever

comes first)

Brake pedal shaft bearings

Dry Moly Lube (CCI P/N 1012151)

Accelerator push rod pivots,

mounts, and shifter cable pivots

Dry Moly Lube (CCI P/N 1012151)

Front suspension (2 fittings)

Chassis Lube (EP NLGI Grade 2)

Check/add brake fluid

Use only DOT-5 (silicone) brake fluid

Annually by trained

technician only

(or every 100 hours of

operation, whichever

comes first)

Check/fill transaxle to plug level

MC012C-AS00 – 29 oz. (.85 liters) 80-

90 Wt. API Class GL-3 or 80-90 Wt.

AGMA Class 5 EP gear lubricant

Inspect front wheel bearings

(Repack as necessary)

Chassis Lube (EP NLGI Grade 2)

First change 100 hours –

additional change

every 200 hours of opera-

tion or annually, whichever

comes first

Change engine oil and oil filter

32 oz. (0.95 liter) without filter; 38 oz.

(1.12 liters) with filter. See Oil Viscosity

on page 35.

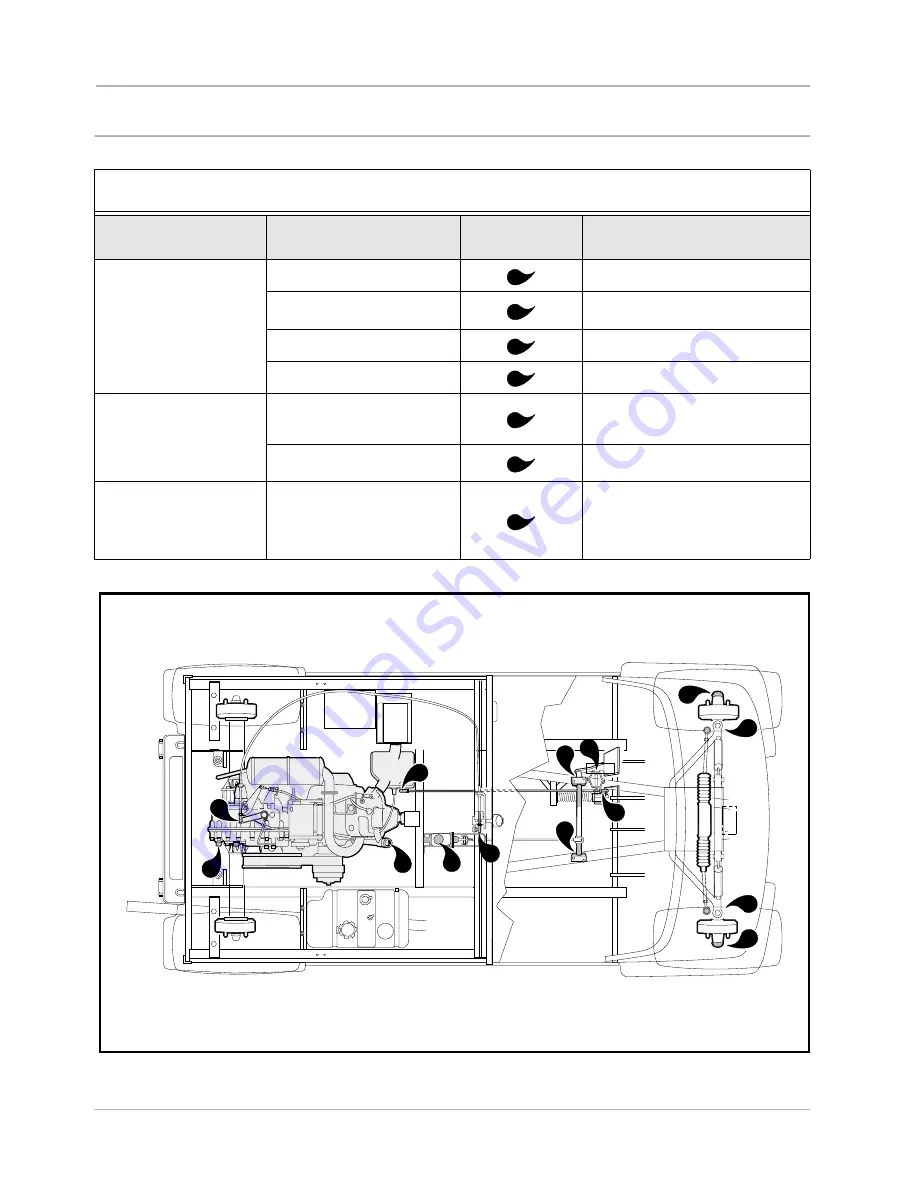

Figure 17 Lubrication Points

1

2

3

4

5

6

7

2

5

1

7

4

2

2

3

6

3

6

2

2

1

FLOORBOARD

Fuel tank is located under front passenger seat on Carryall 472.