16

Exhaust System

DIESEL ENGINE, MUFFLER, FUEL SYSTEM,

AND CLUTCHES

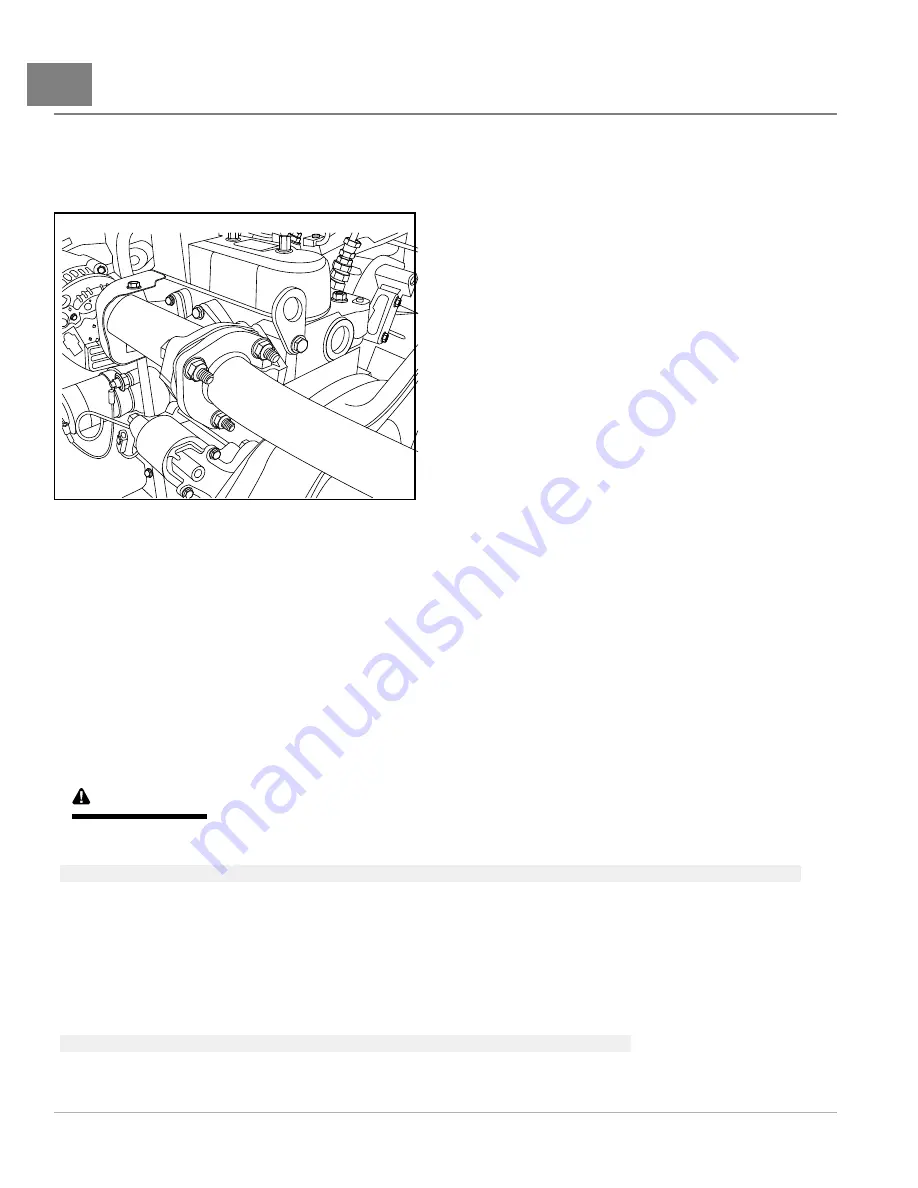

MANIFOLD PIPE REMOVAL

1.

Remove the three bolts and flange-head locknuts

.

2.

Separate the manifold pipe from the engine exhaust manifold.

2181

Figure 16-6

Diesel Manifold Pipe Flange

MANIFOLD PIPE INSTALLATION

1.

Clean both the exhaust manifold and the manifold pipe flanges with a scraper or wire brush.

2.

Use a new high-temperature flange gasket (CC P/N 102422301) and align the manifold pipe so the bend directs

the pipe in and slightly down.

3.

Install new bolts and flange-head locknuts. Tighten the hardware to 21 ft-lb (28.5 N·m)

.

INTERMEDIATE PIPE INSTALLATION

1.

Secure the intermediate pipe to the manifold pipe with new springs.

See following WARNING and NOTE.

WARNING

•

Always wear eye protection when springs are removed or installed.

NOTE:

Shift the end of the muffler inlet and intermediate pipe from side to side to relax and connect the springs.

2.

Secure the intermediate pipe to the muffler inlet with new springs.

See previous NOTE and WARNING.

3.

Align the muffler with the intermediate pipe and tighten the muffler spring suspension bracket bolts to 21 ft-lb (29

N·m).

MUFFLER INSTALLATION

NOTE:

Replace springs that show signs of brittleness, broken coils, or loss of tension.

1.

Loosely secure the muffler and spring suspension bracket to the chassis with two bolts and large flat washers

Page 16-6

2008-2012 All-Wheel Drive Maintenance and Service Manual

Summary of Contents for Carryall 295 SE

Page 2: ......

Page 20: ......

Page 28: ......

Page 58: ......

Page 66: ......

Page 100: ......

Page 122: ......

Page 150: ......

Page 157: ......

Page 190: ......

Page 197: ......

Page 236: ......

Page 284: ......

Page 386: ......

Page 394: ......

Page 442: ......

Page 452: ......

Page 454: ......

Page 455: ......

Page 456: ......