DIESEL ENGINE, MUFFLER, FUEL SYSTEM, AND

CLUTCHES

Clutches

16

CAUTION

• Do not lubricate the drive clutch. Lubricants attract dirt and dust, which interfere with proper clutch

operation.

• Use only a dry cloth and lightly wipe the shaft of the fixed face assembly (15) (Figure 16-35, Page

16-30). Do not use a brush or steel wool. These abrasives will damage the surface of the shaft.

• Do not use solvents. Solvents will damage the lubricating characteristics of the bushings.

2.

Inspect the belt contact surfaces of the clutch sheaves for wear. If any area of a sheave contact surface has

wear of 0.060 inch (1.52 mm) or more, the clutch should be replaced.

Drive Clutch Disassembly – Two-Weight Design

1.

Use a 7/16-inch socket to remove the four bolts (1) and washers (2) that secure the plate (3) to the clutch cover

(4)

.

2.

Remove the cover (4) and spring (5) from the clutch spider (6).

3.

Inspect the torque rollers (7), weights (11) and rollers (10). Replace if necessary.

4.

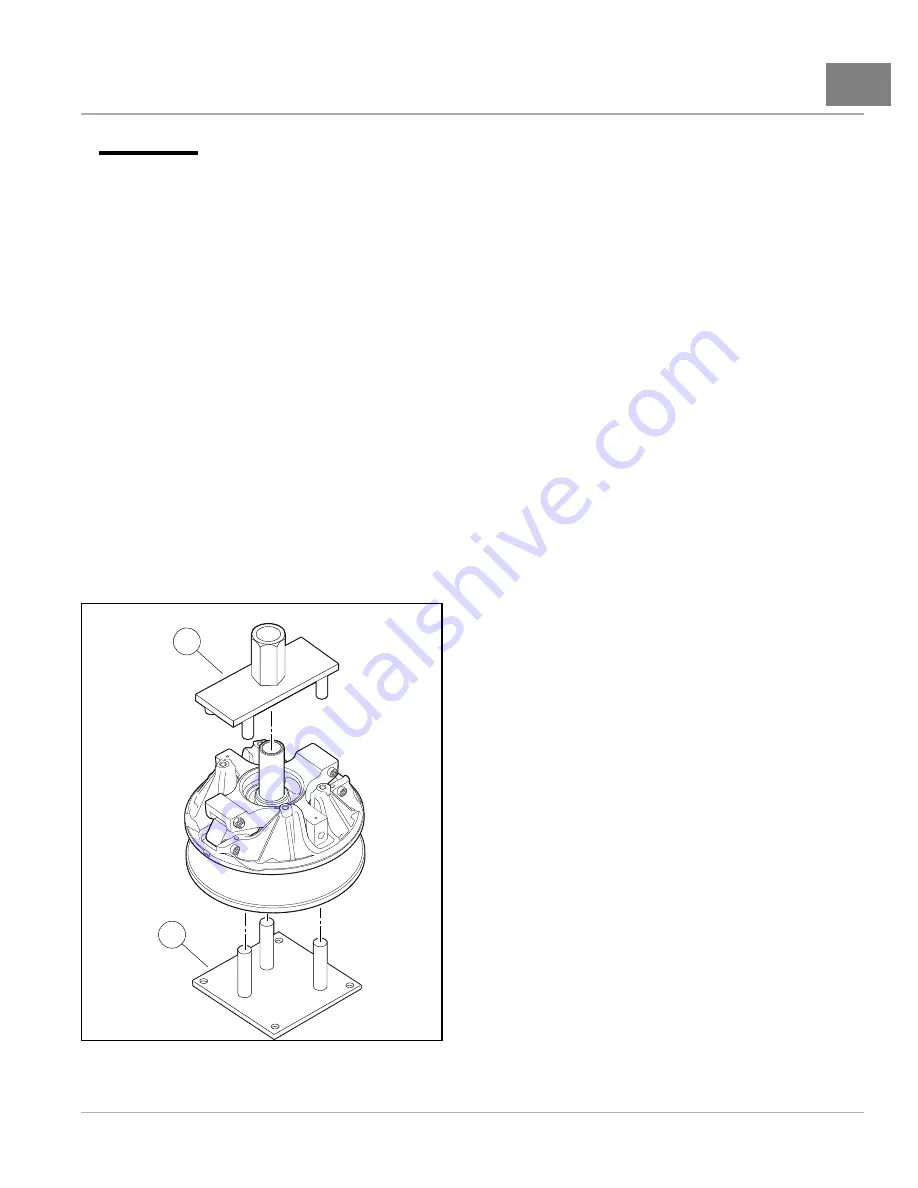

Secure the Fixed sheave tool (CC P/N 102601501) (1) into a vice, or mount the tool to a flat work surface

.

5.

Place the fixed sheave of the drive clutch onto the service tool so that the drive clutch is stationary.

6.

Place the Spider tool (CC P/N 102607501) (2) on top of the spider.

7.

Use a 1/2-inch drive ratchet to disengage the moveable sheave (14) and spider (6), which will come off as an

assembly, from the fixed sheave (15)

1

2

2172

Figure 16-34

Using the Drive Clutch Service Tool

(Two-Weight)

2008-2012 All-Wheel Drive Maintenance and Service Manual

Page 16-29

Summary of Contents for Carryall 295 SE

Page 2: ......

Page 20: ......

Page 28: ......

Page 58: ......

Page 66: ......

Page 100: ......

Page 122: ......

Page 150: ......

Page 157: ......

Page 190: ......

Page 197: ......

Page 236: ......

Page 284: ......

Page 386: ......

Page 394: ......

Page 442: ......

Page 452: ......

Page 454: ......

Page 455: ......

Page 456: ......