19

Attachment Interface

HYDRAULIC ATTACHMENT SYSTEM

3.

Turn the key switch to the OFF position to shut off vehicle. Turn the key switch back to the ON position, but DO

NOT start the utility vehicle engine. Keep the joystick ON/OFF switch set to ON.

4.

Relieve pressure in the desired circuit:

4.1. For the tilt circuit, slightly retract the tilt cylinder to relieve most of the built up pressure.

4.2. For the lift circuit, activate the float feature to relieve pressure.

4.3. For the auxiliary circuit, if equipped, turn the key switch to the OFF position and press the auxiliary hydraulic

switch to the right and then to left several times to relieve pressure.

5.

Once pressure is relieved from the circuit(s) to be serviced, make sure the key switch is in the OFF position and

set the joystick ON/OFF switch to OFF.

ATTACHMENT INTERFACE

INSPECTION

Hand Lever

WARNING

• The pins must extend through the holes in attachment. Lever must be fully engaged in the locked

position. Failure to secure pins can allow attachment to come off and cause injury or death.

2

1

2

2220

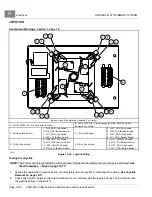

Figure 19-1

Hand Lever

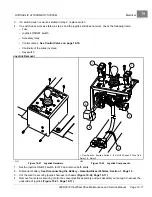

2221

Figure 19-2

Attachment Pins

1.

Move the locking hand lever (1) to engage and disengage the pins (2)

. The lever and

pins must move freely.

2.

The pins (2) must extend through the holes in the attachment mounting frame

. If the pin

does not extend through the hole, the attachment will be loose and can come off the attachment interface.

3.

Inspect the linkages and pins for excessive wear or damage

. Replace any parts that

are damaged, bent or missing. Keep all fasteners tight.

Page 19-2

2008-2012 All-Wheel Drive Maintenance and Service Manual

Summary of Contents for Carryall 295 SE

Page 2: ......

Page 20: ......

Page 28: ......

Page 58: ......

Page 66: ......

Page 100: ......

Page 122: ......

Page 150: ......

Page 157: ......

Page 190: ......

Page 197: ......

Page 236: ......

Page 284: ......

Page 386: ......

Page 394: ......

Page 442: ......

Page 452: ......

Page 454: ......

Page 455: ......

Page 456: ......