HYDRAULIC ATTACHMENT SYSTEM

Cylinders

19

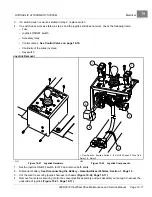

Vehicle Mounted Cylinder Installation

1.

If installing a used cylinder, clean inside the attachment ends first. Otherwise, orient cylinder, align attachment

ends and secure with pivot pin(s) and retaining pin(s).

2.

Match and connect hoses to fittings

. Tighten fittings to 22 ft-lb (30 N·m).

3.

Lubricate attachment ends.

See Lubricating the Attachment Arm and Interface, Section 10, Page 10-7.

4.

Refill and prime system.

See Priming the Pump, Section 19, Page 19-46.

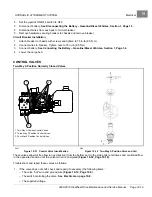

AUXILIARY CYLINDER (OPTIONAL)

Auxiliary Cylinder Removal

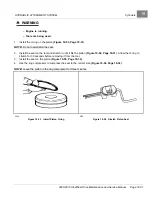

WARNING

• Wear safety glasses to prevent eye injury when any of the following conditions exist:

– Fluids are under pressure.

– Flying debris or loose material is present.

– Engine is running.

– Tools are being used.

CAUTION

• When repairing hydraulic systems, clean the work area before disassembly and keep all parts clean.

Always use caps and plugs on hoses, tubelines and ports to keep dirt out. Dirt can quickly damage

the system.

NOTE:

Contain and dispose of any leaking oil in an environmentally safe manner.

The following pictures may not show your exact attachment but the procedure is the same.

1.

Remove hydraulic hoses (items 1 & 2)

.

See following NOTE.

NOTE:

Mark hoses for correct installation if factory markings are not found.

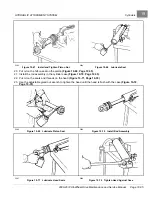

2.

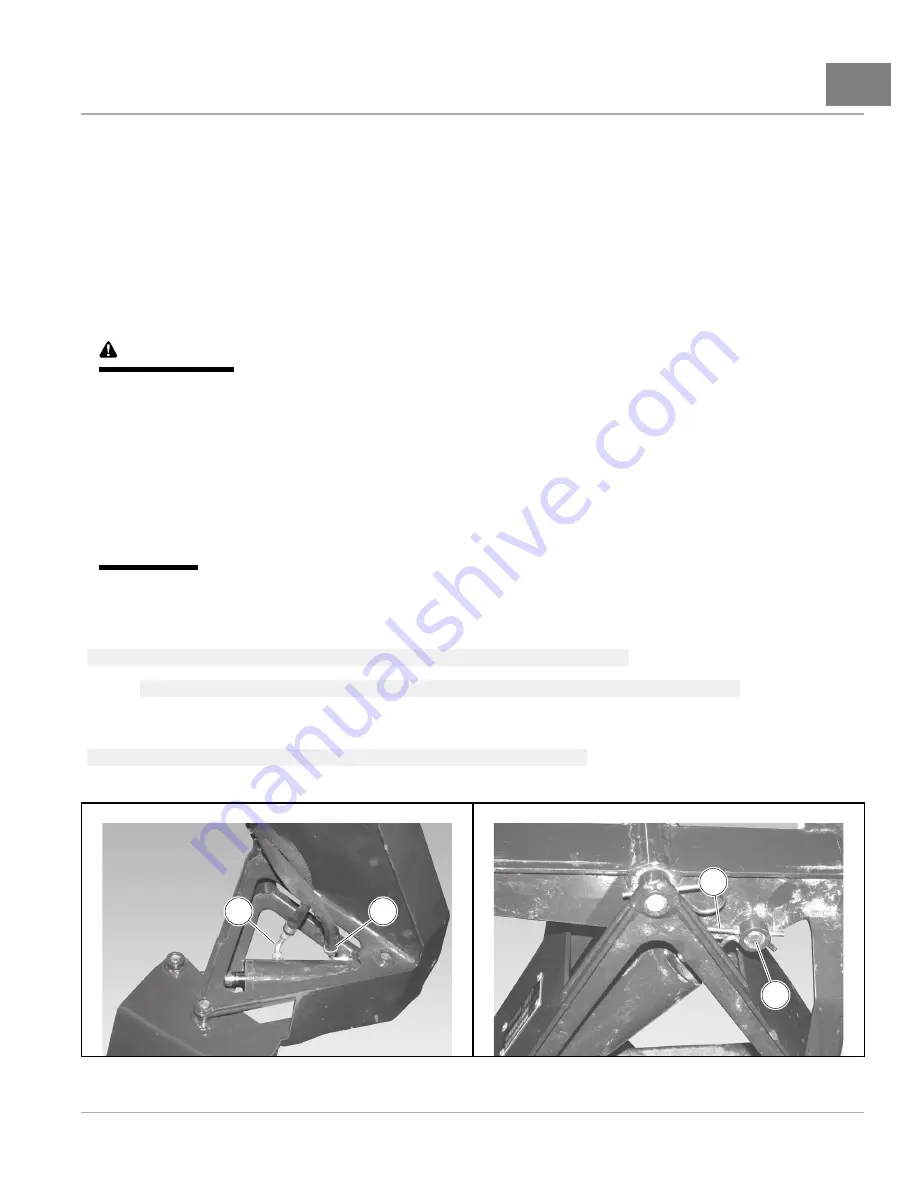

Remove retaining pin (1) and pivot pin (2) from rod end of hydraulic cylinder

.

1

2

1

2

2254

Figure 19-38

Hoses

2255

Figure 19-39

Remove Rod End Pins

2008-2012 All-Wheel Drive Maintenance and Service Manual

Page 19-25

Summary of Contents for Carryall 295 SE

Page 2: ......

Page 20: ......

Page 28: ......

Page 58: ......

Page 66: ......

Page 100: ......

Page 122: ......

Page 150: ......

Page 157: ......

Page 190: ......

Page 197: ......

Page 236: ......

Page 284: ......

Page 386: ......

Page 394: ......

Page 442: ......

Page 452: ......

Page 454: ......

Page 455: ......

Page 456: ......