19

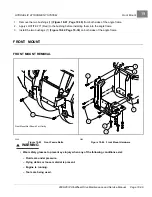

Cylinders

HYDRAULIC ATTACHMENT SYSTEM

WARNING

• Wear safety glasses to prevent eye injury when any of the following conditions exist:

– Fluids are under pressure.

– Flying debris or loose material is present.

– Engine is running.

– Tools are being used

CAUTION

• When repairing hydrostatic and hydraulic systems, clean the work area before disassembly and keep

all parts clean. Always use caps and plugs on hoses, tubelines and ports to keep dirt out. Dirt can

quickly damage the system.

NOTE:

Contain and dispose of any leaking oil in an environmentally safe manner.

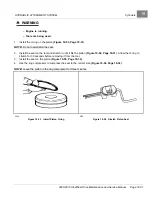

Use the following tools to disassemble and assemble the hydraulic cylinder:

• MEL1074 O-Ring Seal Hook

• MEL1396 Seal Installation Tool

• MEL1032 or MEL1033 Rod Seal Installation Tool

• MEL1075 Adjustable Gland Nut Wrench

• MEL1076 Cylinder Wrench

• Torque Multiplier (See your Ingersoll Rand dealer)

NOTE:

The drawings may not show the cylinder exactly as it appears, but the procedure is correct for all the cylinders.

1.

Put the base end of the hydraulic cylinder in a drain pan.

2.

Move the rod in and out to remove the fluid from the cylinder. Move the rod slowly so the fluid will go directly

into the drain pan.

3.

Put the base end of the cylinder in a vise.

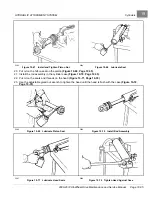

4.

Use an adjustable gland nut wrench to loosen the head

.

5.

Remove the rod assembly from the cylinder case

6.

Remove the cylinder case from the vise.

7.

Put the rod end in the vise.

8.

Remove the nut from the piston end of the rod

9.

Pull the piston (1) off the rod. If the cylinder has a cushion sleeve (2), pull it off the rod. Pull the head (3)

off the rod

Page 19-28

2008-2012 All-Wheel Drive Maintenance and Service Manual

Summary of Contents for Carryall 295 SE

Page 2: ......

Page 20: ......

Page 28: ......

Page 58: ......

Page 66: ......

Page 100: ......

Page 122: ......

Page 150: ......

Page 157: ......

Page 190: ......

Page 197: ......

Page 236: ......

Page 284: ......

Page 386: ......

Page 394: ......

Page 442: ......

Page 452: ......

Page 454: ......

Page 455: ......

Page 456: ......