HYDRAULIC ATTACHMENT SYSTEM

Hydraulic Pump Assembly

19

3.

Wipe/rinse the pump clean.

4.

Clean and inspect reservoir o-ring. Replace if necessary.

5.

Lubricate o-ring with new fluid and install reservoir, being careful not to pinch or deform the o-ring. Tighten

clamp to 57 in-lb (6.3 N·m).

6.

Install pump assembly.

See Pump Assembly Installation on page 19-44.

MOTOR

Motor Removal

2309

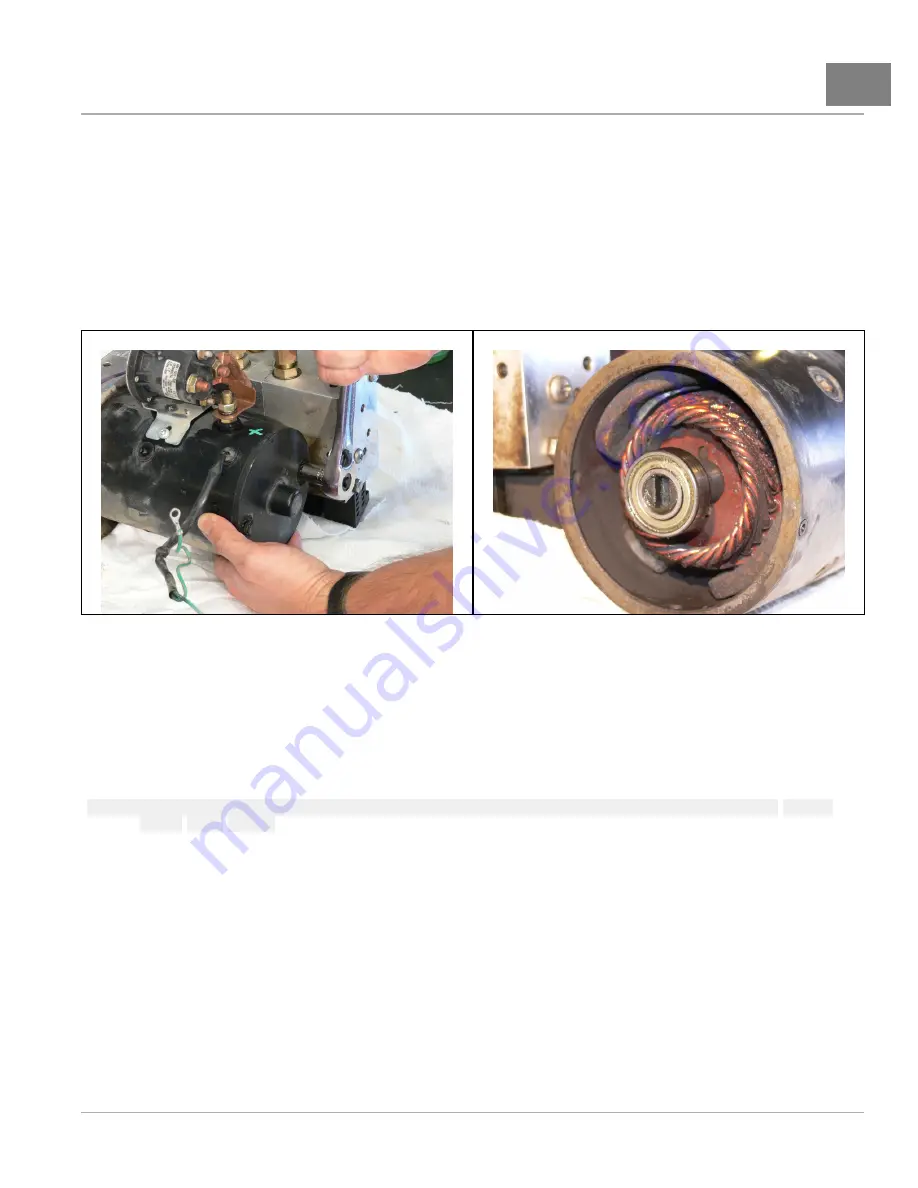

Figure 19-93

Remove Motor Bolts

2310

Figure 19-94

Motor Bearing

1.

Lift pump assembly out of chassis and remove cradle.

See Pump Assembly Removal on page 19-42.

2.

Note location of and disconnect solenoid wires and remove solenoid.

3.

Match-mark the motor housing to ease reassembly alignment.

4.

Remove two bolts and end cover from motor

5.

Grasp motor housing and armature and pull motor from pump.

See following NOTE.

NOTE:

The motor may require effort to remove because the bearing is also being pulled out of the base

Motor Installation

1.

Align slot in motor armature with pump driveshaft and carefully push the motor and bearing into place

19-95, Page 19-46) (Figure 19-96, Page 19-46)

. Once in place, align mark on motor housing with mark on base.

2.

Align hole in end cover with pin on motor housing and install. Secure with bolts previously removed.

3.

Attach solenoid to motor and connect wires.

See Solenoid Installation on page 19-18.

4.

Assemble pump assembly to cradle and place unit in chassis.

See Pump Assembly Installation on page 19-44.

2008-2012 All-Wheel Drive Maintenance and Service Manual

Page 19-45

Summary of Contents for Carryall 295 SE

Page 2: ......

Page 20: ......

Page 28: ......

Page 58: ......

Page 66: ......

Page 100: ......

Page 122: ......

Page 150: ......

Page 157: ......

Page 190: ......

Page 197: ......

Page 236: ......

Page 284: ......

Page 386: ......

Page 394: ......

Page 442: ......

Page 452: ......

Page 454: ......

Page 455: ......

Page 456: ......