4

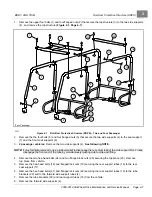

Roll-Over Protective Structure (ROPS)

BODY AND TRIM

ROPS INSTALLATION

NOTE:

Follow steps 1 through 3 for 2-passenger vehicles and steps 1 through 8 for 4-passenger vehicles. ROPS

installation will be easier with the aid of an assistant.

1.

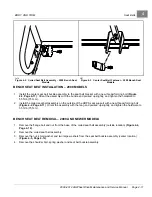

Position the side support tubes (4) to the seat support (7) and front cowl supports (8) and secure with hex-head

bolts (5), and flanged lock nuts (6). Do not tighten hardware at this time.

See following NOTE.

NOTE:

Make sure the front cowl support bolt heads are oriented to outside of the ROPS and the seat support bolt

heads are oriented to the inside of the ROPS.

It may be necessary to tap the side support tubes (4) with a rubber mallet in order for them to align properly

with the front and rear support tubes.

2.

Position the top structure (3) to the top of the side support tubes (4) and secure with hex-head bolts (1), and

flanged lock nuts (2). Do not tighten hardware at this time.

See following NOTE.

NOTE:

Orient the top structure (3) so the grab handle is on the passenger side and the warning decal is visible to

the driver.

3.

Tighten all hardware to 33 ft-lb (45 N·m).

See following WARNING and NOTE.

NOTE:

If any ROPS joints remain loose, apply additional torque up to 40 ft-lb (54 N·m).

WARNING

• Exceeding the maximum torque value could result in damage to the ROPS tubing and stripped threads

on the hardware.

• Ensure that the ROPS is properly installed before operating the vehicle.

4.

Position the two rear support tubes (16) loosely to the rear seat support (17). Do not install hardware at this time.

5.

Secure the rear support tubes (16) to the forward side support tubes (4) with tube brackets (20), using hex-head

bolts (21) and flanged lock nuts (22). Do not tighten hardware at this time.

See following NOTE.

NOTE:

Make sure bolt heads are oriented to the inside of the ROPS.

6.

Lower the two rear support tubes (16) fully into position on the rear seat support (17) and secure with hex-head

bolts (18) and flanged lock nuts (19). Do not tighten hardware at this time.

See following NOTE.

NOTE:

It may be necessary to tap the side support tubes (4) with a rubber mallet in order for them to align properly

with the front and rear support tubes.

7.

Position the top brace (23) to the top of the rear side supports (16) and secure with hex-head bolts (24) and

flanged lock nuts (25).

8.

Tighten all hardware to 33 ft-lb (45 N·m).

See following WARNING and NOTE.

NOTE:

If any ROPS joints remain loose, apply additional torque up to 40 ft-lb (54 N·m).

WARNING

• Exceeding the maximum torque value could result in damage to the ROPS tubing and stripped threads

on the hardware.

• Ensure that the ROPS is properly installed before operating the vehicle.

Page 4-8

2008-2012 All-Wheel Drive Maintenance and Service Manual

Summary of Contents for Carryall 295 SE

Page 2: ......

Page 20: ......

Page 28: ......

Page 58: ......

Page 66: ......

Page 100: ......

Page 122: ......

Page 150: ......

Page 157: ......

Page 190: ......

Page 197: ......

Page 236: ......

Page 284: ......

Page 386: ......

Page 394: ......

Page 442: ......

Page 452: ......

Page 454: ......

Page 455: ......

Page 456: ......