13

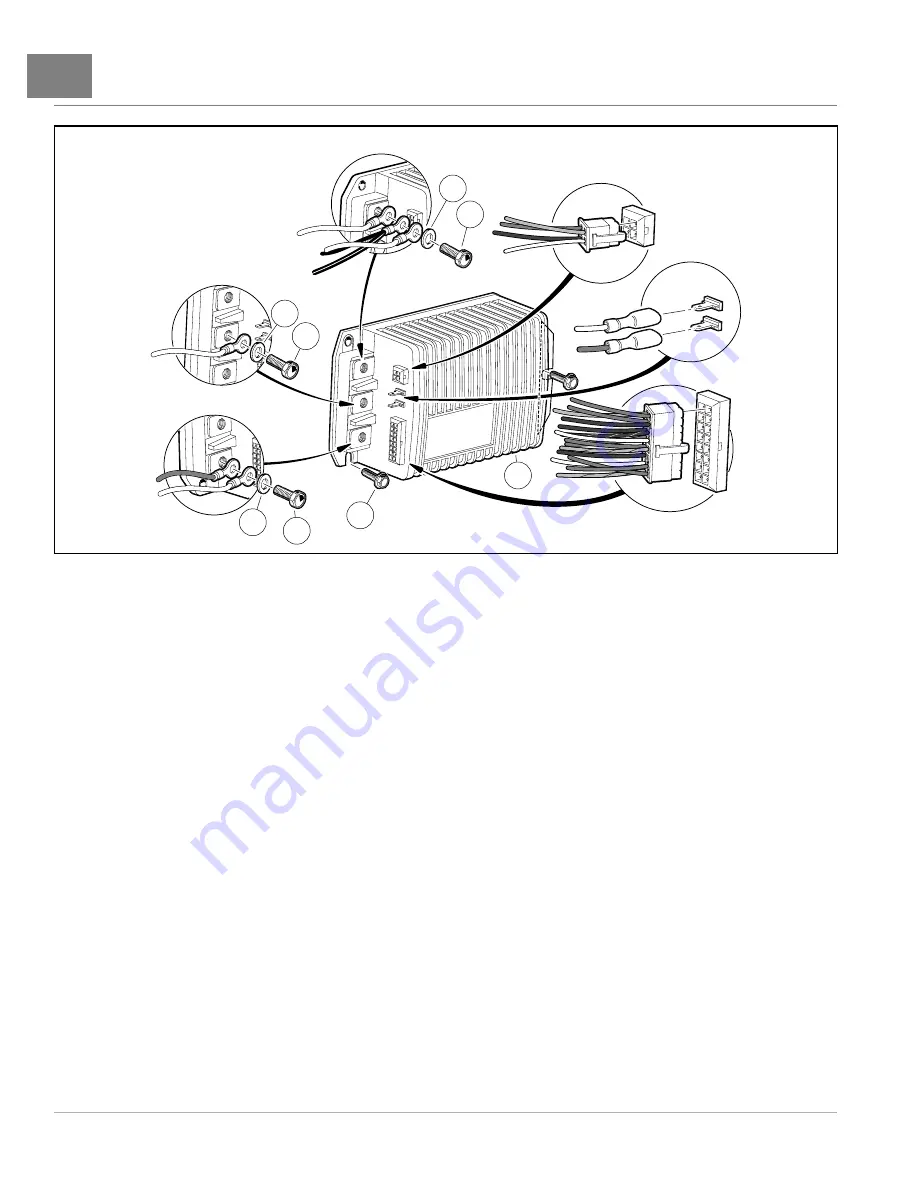

Speed Controller

ELECTRIC VEHICLE - ELECTRICAL

COMPONENTS

2

S

1

S

–

M

+

B

–

B

2

S

1

S

1

1

2

3

6

2

2

1

2901

Figure 13-6

Speed Controller

SPEED CONTROLLER INSTALLATION

1.

Install controller (6) on the two self-tapping screws (3). Install third self-tapping screw (3) and tighten to 5.5

ft·lb (7.5 N·m)

2.

Connect the the heavy gauge wires to the controller (6) per the electrical schematics.

and 10k Ohm Resistor Locations on page 12-4.

Tighten terminal screws (1) on the controller to 108 in·lb

(12.2 N·m).

3.

Connect the 16-pin connector, 4-pin connector, and spade connectors to the controller (6).

4.

Place the Run/Tow switch in the TOW position and connect the batteries.

See Connect the Batteries – Electric

5.

Place the Run/Tow switch in the RUN position.

6.

If vehicle is equipped with the Guardian SVC system, perform the following additional steps for proper setup.

6.1.

Connect a CDT to the CDT port on the vehicle.

6.2.

Select

Program, Settings, Control Mode

and set the value to 1.

6.3.

Select

Program, Settings, Anti Tamper

and set the value to 0.

6.4.

Select

Program, Vehicle ID, Vehicle S/N

and enter the last six digits of the vehicle serial number.

NOTE:

The speed for scrolling values may be increased by utilizing the bookmark keys (yellow buttons) in combination

with the data inc/dec key (+/-).

6.5.

Select

Program, Vehicle ID, Vehicle Decal

and enter the number on the Vehicle Number Decal.

6.6.

Select

Program, Vehicle ID, Vehicle Date of Manufacture

and enter the number on the model year and

week from the vehicle serial number.

6.7.

Select

Information, Software Version

and verify the value is 13 or higher. If not, contact a Club Car

Technical Representative.

Page 13-8

2021 Carryall 300 Maintenance and Service Manual

Summary of Contents for Carryall 300 2021

Page 2: ......

Page 16: ......

Page 551: ...80 2018 by Kohler Co All rights reserved KohlerEngines com 17 690 15 Rev...

Page 565: ...GASOLINE ENGINE HARNESS Wiring Diagrams Gasoline Engine Harness 26...

Page 566: ...Page intentionally left blank...

Page 567: ...GASOLINE KEY START MAIN HARNESS Wiring Diagrams Gasoline Key Start Main Harness 26...

Page 568: ...Page intentionally left blank...

Page 569: ...GASOLINE PEDAL START MAIN HARNESS Wiring Diagrams Gasoline Pedal Start Main Harness 26...

Page 570: ...Page intentionally left blank...

Page 571: ...GASOLINE INSTRUMENT PANEL HARNESS Wiring Diagrams Gasoline Instrument Panel Harness 26...

Page 572: ...Page intentionally left blank...

Page 573: ...GASOLINE FNR HARNESS Wiring Diagrams Gasoline FNR Harness 26...

Page 574: ...Page intentionally left blank...

Page 575: ...ELECTRIC MAIN HARNESS Wiring Diagrams Electric Main Harness 26...

Page 576: ...Page intentionally left blank...

Page 577: ...ELECTRIC INSTRUMENT PANEL HARNESS Wiring Diagrams Electric Instrument Panel Harness 26...

Page 578: ...Page intentionally left blank...

Page 579: ...ELECTRIC ACCESSORIES HARNESS Wiring Diagrams Electric Accessories Harness 26...

Page 580: ...Page intentionally left blank...

Page 588: ...NOTES...

Page 589: ...NOTES...

Page 590: ...NOTES...

Page 591: ...NOTES...

Page 592: ...NOTES...

Page 593: ...NOTES...

Page 594: ...NOTES...

Page 595: ......

Page 596: ......