Battery

Page 58

2007 Carryall 295 Intellitach and XRT 1550 Intellitach Diesel Vehicle Owner’s Manual

BATTERY

See General Warnings on page 8.

ý

DANGER

• Battery – Explosive gases! Do not smoke. Keep sparks and flames away from the vehicle and

service area. Ventilate when charging or operating vehicle in an enclosed area. Wear a full

face shield and rubber gloves when working on or near batteries.

• Battery – Poison! Contains acid! Causes severe burns. Avoid contact with skin, eyes, or

clothing. Antidotes:

- External: Flush with water. Call a physician immediately.

- Internal: Drink large quantities of milk or water followed with milk of magnesia or vegetable

oil. Call a physician immediately.

- Eyes: Flush with water for 15 minutes. Call a physician immediately.

• Tools, wires, and metal objects can cause sparks when shorted across a battery.

ý

WARNING

• Wear safety glasses or approved eye protection when servicing the vehicle.

• Follow all instructions carefully when working with batteries.

• When jumping from a booster battery make final (negative) connection at engine frame.

• Do not jump start or charge a frozen or damaged battery. Unplug charger before connecting

or disconnecting cables to the battery. Never lean over battery while boosting, testing, or

charging.

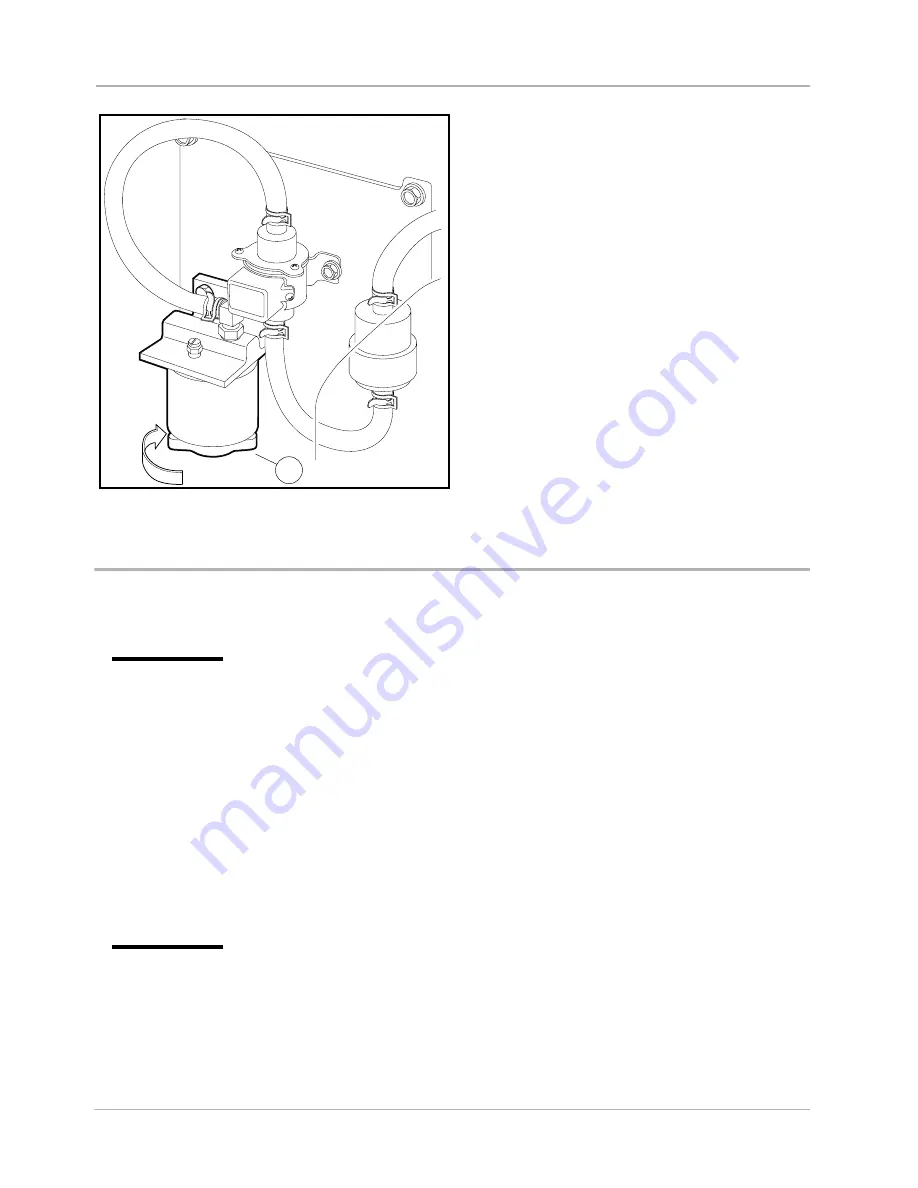

Figure 63 Fuel Filter

1