UNITIZED TRANSAXLE

General Information

Page 16-2 2001 Pioneer 900 Gasoline Vehicle Maintenance and Service Manual

16

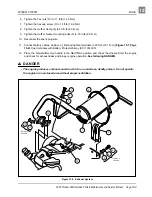

Shifter Lever

A shifter lever, connected to a shifter arm on the unitized transaxle, is used to change the gears to one of

three shift positions: FORWARD (F), NEUTRAL (N), or REVERSE (R) (Figure 16-1, Page 16-2). The vehicle

should come to a complete stop before changing FORWARD or REVERSE direction.

Lockout Cam

The Pioneer 900 vehicle has a lockout circuit that prevents a driver from starting the vehicle when it is in

gear. The engine can be started only when the Forward/Reverse handle is in the NEUTRAL position. See

Lockout Cam Circuit, Section 11, Page 11-11.

Governor System

The governor system is a flyweight type, and regulates vehicle ground speed. It is mounted inside the unit-

ized transaxle and is driven by transaxle gears. Because the governor is mounted inside the transaxle, it is

protected from abuse and damage common to externally mounted governor systems. If any of the governor

linkages are removed in order to service other components, readjustment of the governor linkage is required.

See Governor Cable Installation and Adjustment, Section 14, Page 14-11.

Unitized Transaxle Service

The unitized transaxle is extremely durable and should require very little service under normal operating con-

ditions. The only maintenance required on the unitized transaxle is to maintain proper lubricant level. See

Periodic Lubrication Schedule, Section 10, Page 10-4. Under normal operating conditions, adjustment to

the system should not be required.

Tools Required For This Section

Figure 16-1 Shifter Positions

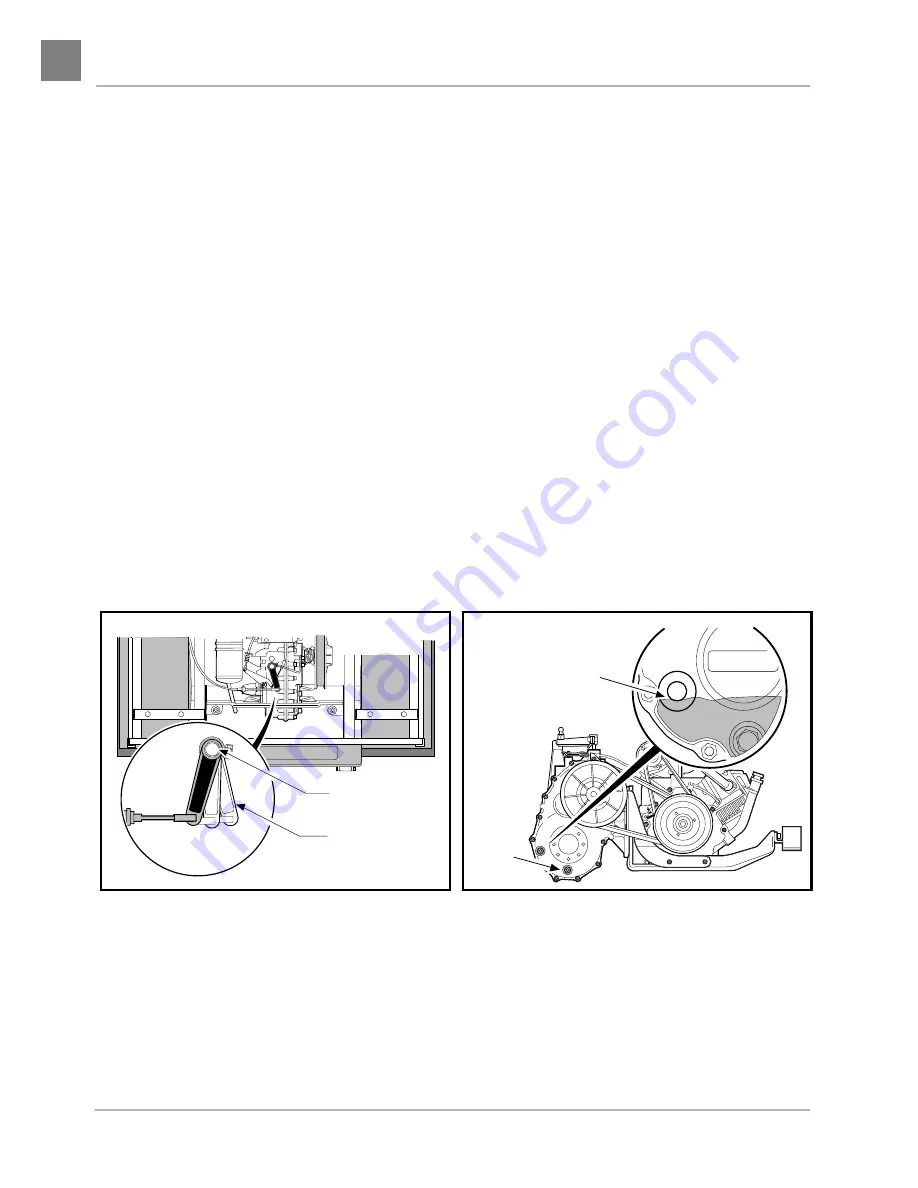

Figure 16-2 Lubricant Level

Hydraulic floor jack (or chain hoist)

12 to 18 in. straight edge

17 mm socket, 3/8 in. drive

Jack stands (2) (one ton capacity)

Small ball peen hammer (10 oz.)

7/16 combination wrench

Hydraulic press

Plastic or rubber mallet

1/2 combination wrench

Bench vise

Ratchet wrench, 3/8 drive

9/16 combination wrench

TOP VIEW

SHIFTER

LEVER

SHIFTER

SHAFT

F N R

DRAIN

PLUG

C l u b C a r

Lubricant

should be level

with bottom of

level indicator hole.