TORQUE CONVERTER

Driven Clutch

Page 17-14 2001 Pioneer 900 Gasoline Vehicle Maintenance and Service Manual

17

DRIVEN CLUTCH INSPECTION

1. Inspect the cam (4) for excessive wear. Replace it if necessary (Figure 17-16, Page 17-12).

2. Inspect the drive buttons (6) for excessive wear. Replace if necessary. To remove the drive buttons,

remove the socket head cap screws and then the buttons (Figure 17-16, Page 17-12).

3. Inspect the smooth surface on the fixed and moveable face assemblies. Assemblies must be replaced

if surfaces are worn more than 0.060 inch (1.5 mm).

4. Inspect the bronze bearing in the moveable face. If the bearing bore diameter is more than 1.384

inches (35.15 mm), the entire moveable face assembly must be replaced.

5. Inspect the shaft of the fixed face assembly. There should be no measurable wear. Replace the shaft if

it is worn, scratched or damaged.

DRIVEN CLUTCH ASSEMBLY

1. Place the three drive buttons (6) in position. Apply one drop of Loctite® 222 to each of the socket head

cap screws and then install and tighten them to 8 in-lb (0.9 N·m) (Figure 17-16, Page 17-12).

2. Slide the moveable face assembly (7) onto the fixed face shaft (8).

3. Place the end of the spring (5) into the hole in the moveable face assembly.

4. Install the key (3) into the keyway of the fixed face assembly (8) shaft.

5. Holding the cam (4) in position for assembly on the shaft, install the other end of the spring (5) into the

center spring hole of the cam. Rotate the cam until the keyway is aligned with the key (3) on the fixed

face assembly, and then start the cam onto the shaft approximately 1/4 to 3/8 inch (6.3 to 9.5 mm).

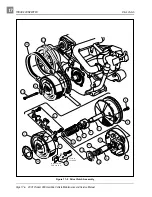

Figure 17-17 Remove Retaining Ring

Figure 17-18 Driven Clutch Disassembly

4

Using external snap

ring pliers, remove

retaining ring.

A

PULLER PLUG

Place puller plug in bore of

cam (A). Then clamp driven

clutch cam puller onto three

flat surfaces of the cam.

DRIVEN CLUTCH

CAM PULLER