STEERING AND FRONT SUSPENSION

Front Wheel Bearings and Hubs

Page 7-20 2001 Pioneer 900 Gasoline Vehicle Maintenance and Service Manual

7

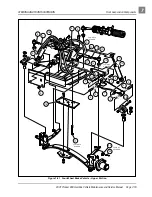

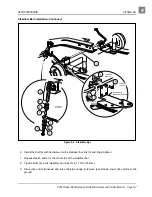

DELTA A-PLATE REMOVAL

1. Loosen lug nuts on both front wheels and raise front of the vehicle with a chain hoist or floor jack. Place

jack stands under the front cross tube of the vehicle frame and lower the vehicle onto the jack stands.

2. Remove wheel. Remove bolts (10 and 24), A-Plate straps (14), and nuts (5) (Figure 7-21, Page 7-19).

3. Remove the lower shock absorber mounting nut (9), then slide the shock absorber free of the Delta A-

Plate (Figure 7-21, Page 7-19).

4. Remove the Delta A-Plate (1) (Figure 7-21, Page 7-19).

5. Inspect the bushings (2) and sleeves (3 and 4) in the Delta A-Plate and replace them if necessary (Fig-

DELTA A-PLATE INSTALLATION

1. Install the A-Plate in reverse order of removal. Tighten the A-Plate suspension bolts (10 and 24) to 20

ft-lb (27 N·m) (Figure 7-21, Page 7-19).

2. Install the wheels and adjust the wheel alignment. See Wheel Alignment on page 7-15.

SHOCK ABSORBER REMOVAL AND INSPECTION

1. Inspect the shock absorbers for fluid leakage at the point where the shaft enters the shock absorber

body. Leaking shock absorbers should be replaced.

2. Remove the nut (9) attaching the shock absorber to the A-Plate (Figure 7-21, Page 7-19).

3. Remove the nut (5) and bolt (8) attaching the shock absorber to the shock and gear support (Figure 7-

4. Remove the shock absorber.

SHOCK ABSORBER INSTALLATION

NOTE: When installing shock absorbers, make sure front shocks have identical part numbers and rear

shocks have identical part numbers.

1. Install the shock absorber by reversing the removal procedure.

2. Tighten the nuts to 20 ft-lb (27 N·m).

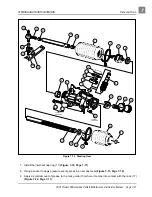

FRONT WHEEL BEARINGS AND HUBS

Read WARNING on page 7-1.

FRONT WHEEL FREE PLAY INSPECTION

1. Raise the front of the vehicle.

2. Using your hands, attempt to rock the wheel and hub assembly back and forth on the spindle. If there is

any observable movement of the wheel and hub on the spindle, remove dust cap (1) and cotter pin (2)

and then tighten the spindle nut (3) until the bearing (5) fully seats in the bearing race (7) (Figure 7-23,