17

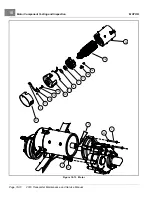

Axle Bearing and Shaft

TRANSAXLE

Axle Shaft and Oil Seal Installation

1.

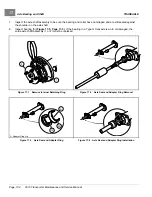

If previously removed, install a new oil seal.

1.1.

Clean seal seat in the adapter ring (39)

.

1.2.

Place a new seal (15) in the adapter ring with the seal lip facing toward the adapter ring lip

. Use an axle seal tool and mallet to tap it in until it seats firmly in position

. A hydraulic press may also be used with the axle seal tool.

1.3.

Clean adapter ring seat(s) in the axle tube (14 or 35)

1.4.

Apply Loctite

®

603 to the outer diameter of the adapter ring.

1.5.

Place the oil seal and adapter ring assembly into the axle tube with the seal lip facing away from the bearing

. Use an axle seal tool and mallet to tap it in until it seats firmly in position.

See

following CAUTION.

CAUTION

• Clean any residual oil from the exposed end of the axle shaft and from the oil seal area prior to

installing the axle shaft to prevent oil from coming in contact with brakes.

2.

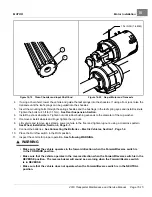

Install the rear axle into the transaxle.

See following NOTE.

2.1.

Insert the shaft, splined end first, through the seal and into the axle tube. Be careful not to damage the seal

on the inside of the axle tube hub. Advance the shaft through to the bearing on the shaft, then rotate it to

align the shaft splines with the splined bore of the differential side gear (27)

.

Continue advancing the shaft until the bearing on the axle is firmly seated within the axle tube hub seat.

2.2.

Use a pair of snap ring pliers to install the retaining ring (6) inside axle tube hub so that it seats against

the axle bearing assembly and into the machined slot in the inside wall of the axle tube hub

.

See following NOTE.

NOTE:

If the retaining ring (6), axle bearing (5), or sleeve (4) must be replaced, the entire axle shaft assembly (1

or 2) must be replaced

.

2.3.

Place a 1/4 to 3/8-inch (6 to 10 mm) diameter rod against the retaining ring and tap lightly at four to five

locations around the retaining ring to ensure it is properly seated.

See following WARNING.

WARNING

• Be sure the retaining ring is properly seated in its groove. If the ring is not properly installed, the axle

assembly will separate from the transaxle and damage the axle assembly and other components. Loss

of vehicle control could result, causing severe personal injury or death.

3.

If a new oil seal was installed, allow 24 hours before operating the vehicle to allow the Loctite 603 to fully cure.

4.

Connect the batteries.

See Connecting the Batteries – Electric Vehicles, Section 1, Page 1-4.

AXLE BEARING

Do not remove the axle bearing (5) from a Type G transaxle. If bearing is worn or damaged, the entire axle assembly

(1 or 2) must be replaced

Page 17-4

2019 Transporter Maintenance and Service Manual

Summary of Contents for TransPorter 4

Page 2: ......

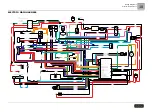

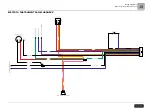

Page 271: ...ELECTRIC MAIN HARNESS Wiring Diagrams Electric Main Harness 18 ...

Page 272: ... Page intentionally left blank ...

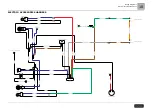

Page 273: ...ELECTRIC INSTRUMENT PANEL HARNESS Wiring Diagrams Electric Instrument Panel Harness 18 ...

Page 274: ... Page intentionally left blank ...

Page 275: ...ELECTRIC ACCESSORIES HARNESS Wiring Diagrams Electric Accessories Harness 18 ...

Page 276: ... Page intentionally left blank ...

Page 282: ...NOTES ...

Page 283: ...NOTES ...

Page 284: ...NOTES ...

Page 285: ......

Page 286: ......