10

3. Move the manual disconnect switch handle to the

“ON” position.

4. Depress the

(up) control. If the hook moves in the

up direction, the hoist is ready for operation. If the

hook lowers, move the disconnect switch handle to

the “OFF” position and interchange the BLACK and

RED leads at the disconnect switch. Move the discon-

nect switch handle to the “ON” position and the

hoist is now ready for operation.

NOTE:

DO NOT CHANGE INTERNAL WIRING OF

HOIST OR CONTROL STATION TO REVERSE

HOOK DIRECTION. THE HOIST AND CONTROL

STATION WIRING WAS INSPECTED AND TEST-

ED FOR PROPER OPERATION AT THE FACTORY.

CHANGING THIS WIRING WILL CAUSE IMPROP-

ER OPERATION AND SERIOUS DAMAGE.

Also, do not force the Protector to compensate for improperly

adjusted limit switches or reverse voltage phasing.

CHECKING FOR TWIST IN LOAD CHAIN

3, 4 And 5 Ton Double Reeved Units

The best way to check for this condition is to run the

lower hook, without a load, up to within about 2 feet

(0.6M) of hoist. If the dead end of chain has been proper-

ly installed, a twist can occur only if the lower hook block

has been capsized between the strands of chain. Reverse

capsize to remove twist.

5,6 And 7 1/2 Ton Triple Reeved Units

On these models, the load chain is dead ended on top of

the lower hook block. If chain has been properly installed,

the only way a twist can occur is if the lower hook block

has been capsized between the strands of chain. If this

has occurred, two strands of chain will be wrapped

around each other and to remove twist, reverse the cap-

size.

CHECKING FOR ADEQUATE VOLTAGE AT HOIST

The hoist must be supplied with adequate electrical

power for proper operation and to reduce problems that

may result from insufficient power (low voltage). These

include:

• Noisy hoist operation due to brake and/or contactor

chatter.

• Heating of the hoist motor and other internal

components as well as heating of wires and con-

nectors in the circuit feeding the hoist.

• Failure of the hoist to lift the load due to motor

stalling.

• Blowing fuses or tripping circuit breakers.

For proper operation and to avoid these low voltage

problems, voltage (measured at the end of the 2.5 foot

(.9 M) power cord while lifting rated load) should be as

follows:

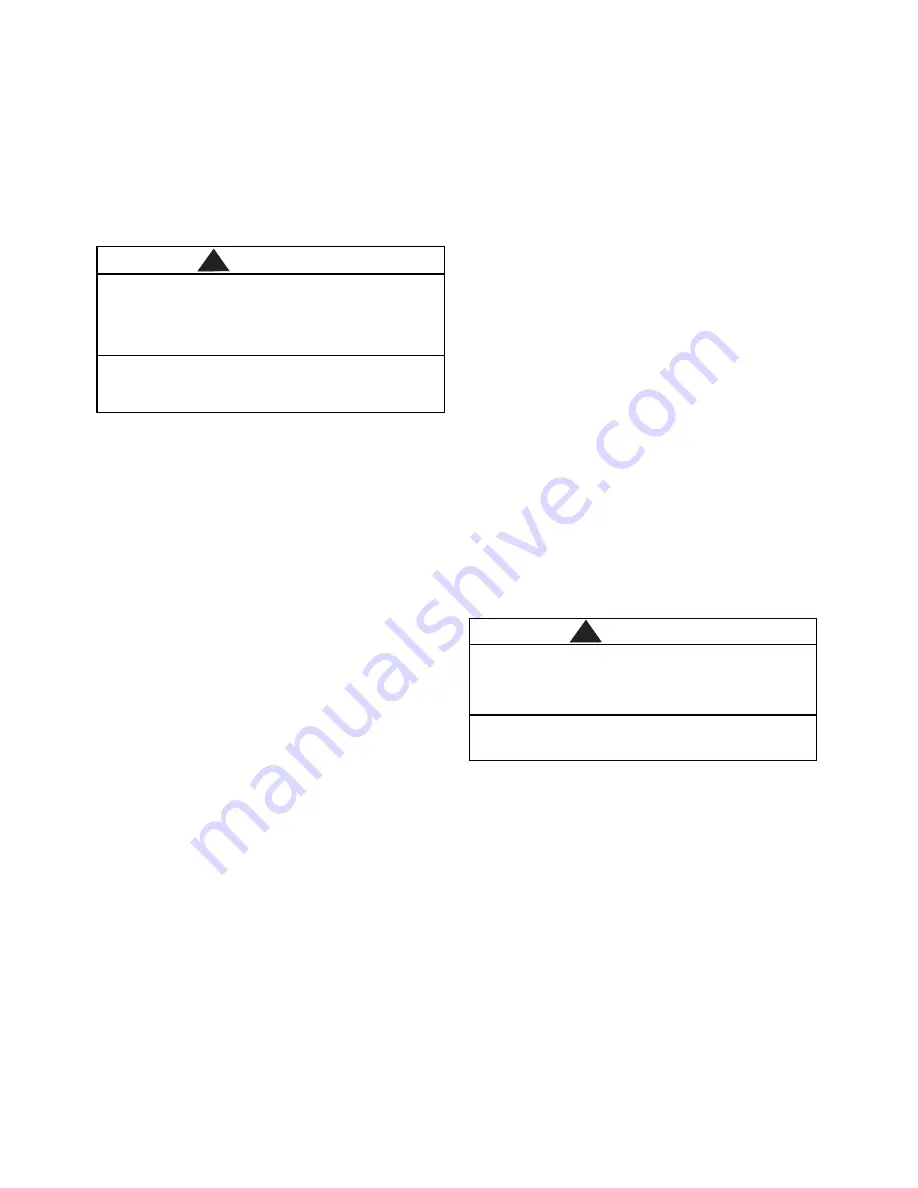

WARNING

Allowing the hook block to run into the bottom of

the hoist when raising a load or allowing the chain to

become taut between the loose end screw and the

frame when lowering a load may break the chain and

allow the load to drop.

TO AVOID INJURY:

Do not allow the hook block to contact the bottom of

the hoist or the loose end chain to become taut.

!

NOMINAL

MINIMUM

* MIN. VOLTAGE

POWER

OPERATING

AT INSTANT

SUPPLY

VOLTAGE

OF START

208-3-60

187

172

220-3-50

198

182

230-3-60

207

190

380-3-50

365

336

415-3-50

399

367

460-3-60

414

380

* The drop in voltage upon energizing the hoist should

not be below the value listed.

Remember, operation with low voltage can void the

Repair/Replacement policy. When in doubt about any of

the electrical requirements for the power supply system,

consult a qualified electrician.

CHECKING LIMIT SWITCH OPERATION

1. Press the

(Up) control and raise the lower hook

until the top of the hook block is about one foot

(0.3M) below hoist.

2. Cautiously continue raising the hook until upper

limit switch stops upward motion. At this point, the

top of the hook block should be 3 inches (76 mm)

below bottom of the hoist.

3. If adjustment is necessary, see page 16.

4. Press

(Down) control and cautiously lower hook until

lower limit switch stops the downward motion. From

10 to 12 chain links should be between the loose end

link and the opening for the chain in bottom of hoist.

If adjustment is necessary, see page 16.

CHAIN CONTAINER

If a chain container is to be used, attach it to the hoist

frame and place chain in container per instructions provid-

ed with the chain container kit. After the chain container

is installed, follow the instructions on page 16 to reset

upper limit switch so uppermost point of hook travel is

just below the bottom of the chain container.

UNDER NO CIRCUMSTANCES SHOULD THE HOOK

BLOCK OR LOAD BE PERMITTED TO COME IN CON-

TACT WITH THE CHAIN CONTAINER. IF CONTACT IS

MADE, THE FUNCTION OF THE CHAIN CONTAINER CAN

BE INTERFERED WITH, THE CONTAINER MAY BE DAM-

AGED AND IT COULD FALL OFF OF THE HOIST.

CONTROL CORD

Unless ordered on a special basis, the hoist is supplied

with a control cord that will position the control station

approximately 4 feet (1.2M) above the lower hook when

it is at the lower limit of lift. If this places the control sta-

tion too close to the floor, a “control cord alteration kit”

(Key No. 627-474, Part Number 28642) can be obtained

from factory for shortening the length of the control

cord.

WARNING

Allowing the hook block to run into the bottom of

hoist when raising a load or allowing the chain to

become taut between the loose end screw and the

frame when lowering a load may break the chain and

allow the load to drop.

TO AVOID INJURY:

Do not allow the hook block to contact the bottom of

hoist or the loose end chain to become taut.

!