Reviews:

No comments

Related manuals for GR Painting Robot Series

iPigeon

Brand: TOPigeon Pages: 2

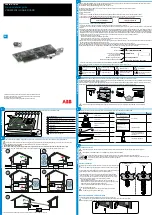

VSN300

Brand: ABB Pages: 2

VSN700

Brand: ABB Pages: 32

RapidRH L6 with Bluetooth

Brand: DATAGRABBER Pages: 11

MSX-E1721

Brand: Addi-Data Pages: 8

TDL2

Brand: Blulog Pages: 19

942 Series

Brand: Watlow Pages: 63

OM-SQ2020 Series

Brand: Omega Engineering Pages: 24

RTDTemp101A

Brand: MadgeTech Pages: 4

nebolink

Brand: NEBO Pages: 4

PROTON S100

Brand: ADAPT LOGGERS Pages: 2

HiTemp1400

Brand: MadgeTech Pages: 2

LmNet - PRO 614-00

Brand: G-Tek Pages: 53

Ultra 2 TGU-4550

Brand: Tinytag Pages: 2

KISTOCK KP 110-RF

Brand: sauermann Pages: 9

Kimo Kistock 320 Series

Brand: sauermann Pages: 20

Class 320

Brand: sauermann Pages: 24

MicroRX RX210 Series

Brand: Hobo Pages: 2