Chapter 7 - Options

7-8

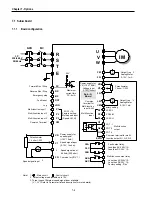

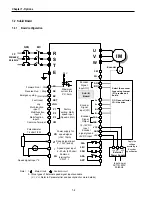

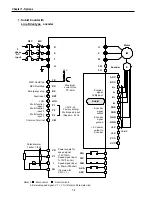

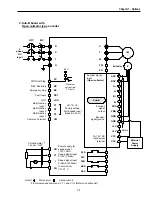

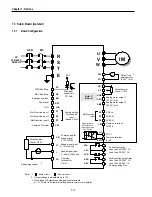

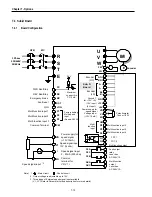

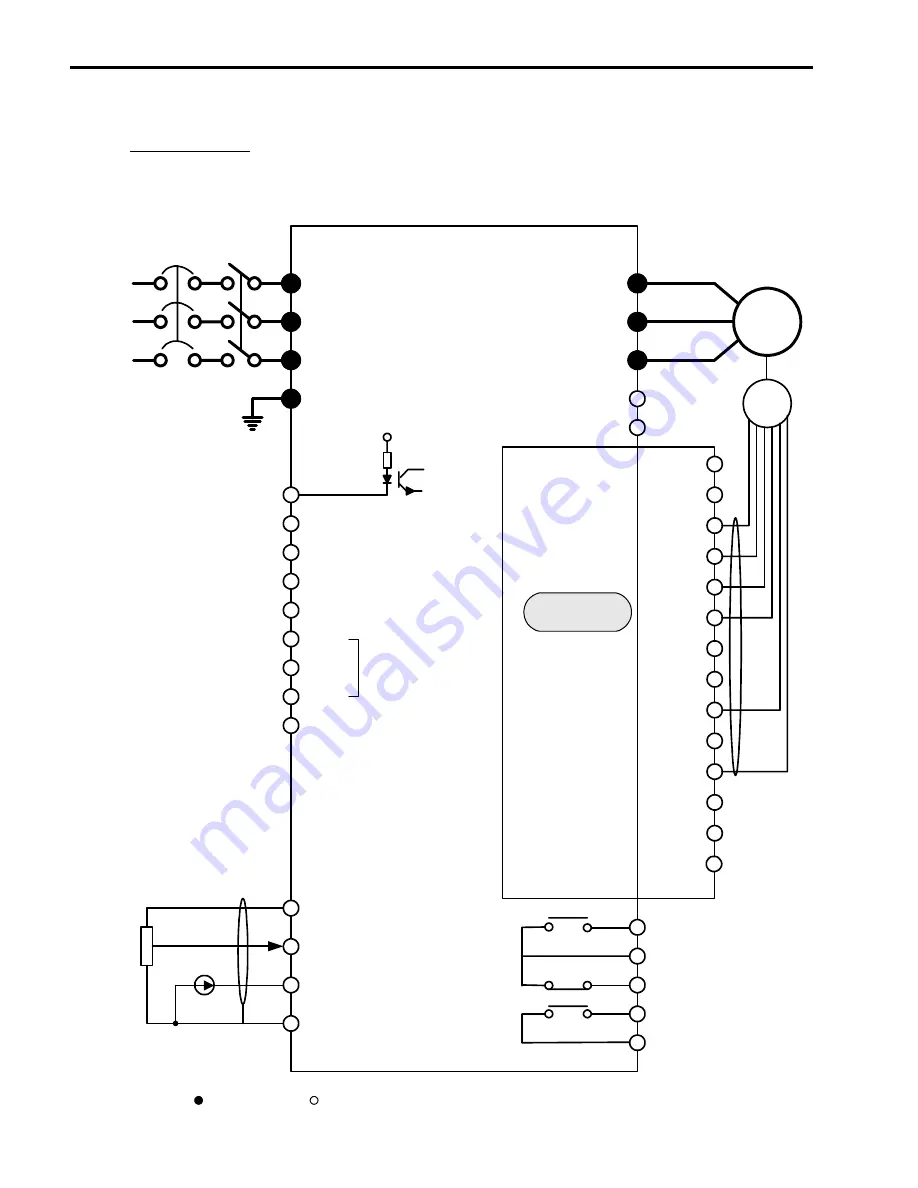

AOC

R

S

T

G

U

V

W

FX

RX

BX

RST

JOG

P1

P2

P3

CM

VR

V1

5G

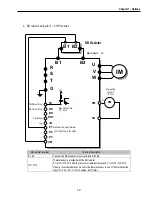

IM

Motor

3

phase

AC

input

BOC

A+

A-

B+

B-

FBA

FBB

GND

E

Encoder

GND

+5V

+5V

VCC

VCC

Sub-B

MC

NFC

FWD Run/Stop

REV Run/Stop

Emergency stop

Fault reset

JOG

I

Potentiometer

1 kohm, 1/2W

24 V

FM

5G

30A

30C

30B

AXA

AXC

Encoder

signal

(LD)

input

Encoder

signal

output

Encoder

signal

ground

Note) 1. : Main circuit, : Control circuit.

2. External speed signal: V1, I, V1+I (Refer to Parameter list)

Shield

+5 V power

output to

Encoder

1. Sub-B board with

Line Drive type encoder

I/O-12~14 :

Factory setting:

Multi-speed input

(Speed-L, M, H)

Common Terminal

Multi-function

input 1

Multi-function

input 2

Multi-function

input 3

Power supply for

speed signal

+12V 10mA

Speed signal input

0~10V(1 kohm)

Speed signal input

4~20mA (250ohm)

(Common for

VR, V1, I )

Maximum

current thru

PC: 5mA

Summary of Contents for 30 HP30

Page 6: ......

Page 12: ......

Page 16: ...Chapter 1 Installation 1 4 BLANK ...

Page 18: ...Chapter 1 Installation 1 6 BLANK ...

Page 28: ...Chapter 1 Installation 1 16 Notes ...

Page 39: ...Chapter 2 Operation 2 11 Notes ...

Page 40: ......

Page 46: ......

Page 60: ...Chapter 4 Operation Examples 4 14 Notes ...

Page 83: ...Chapter 5 Parameter List 5 23 Notes ...

Page 84: ......

Page 92: ...Chapter 6 Parameter Description DRV 6 8 Notes ...

Page 105: ......

Page 106: ...Chapter 6 Parameter description FU1 6 14 Notes ...

Page 126: ...Chapter 6 Parameter Description FU2 6 34 Notes ...

Page 144: ...Chapter 6 Parameter Description I O 6 52 Notes ...

Page 162: ......

Page 188: ...Chapter 7 Options 7 26 Type 1 Max 400 Watt Type 2 Max 600 Watt A ...

Page 189: ...Chapter 7 Options 7 27 Type 3 ...

Page 194: ......

Page 204: ......

Page 210: ......