Page 5

Boiler type

Production year

Serial no.

Yield

Max. op. temperature

Test pressure

Oper. pressure

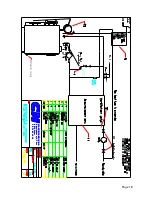

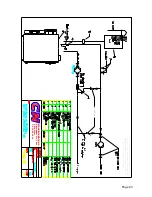

Boiler with cooling spiral

Boilers can be ordered with a cooling spiral, and this must be used for installation with pressure expansion,

and in open systems if the pressure in the boiler is above 0.5 bar over pressure.

The cooling spiral must only be used as a cooling spiral; it must not be used for heating up water for other

use. Therefore the cooling spiral must be left empty during operation. Water supply for cooling spiral

maximum 15 °C. Pressure for cooling spiral minimum 2 bar, maximum 10 bar.

Responsibilities

The user is responsible for the operation of the boiler and ensuring compliance with the operational

guidelines supplied by CN MASKINFABRIK A/S. Failure to comply with the guidelines may result in reduced

efficiency and increased negative effects on the environment, as the boiler will not achieve as clean emission

gasses as intended. Furthermore, incorrect operation can reduce the working life of the boiler.

Correct operation and installation are the best guarantees for a well-functioning boiler with a long life and a

good environment. The user needs to have the necessary willingness and correct attitude to burning wood,

as it does, after all, take a bit of work to ”yield the crops” of this environmentally friendly and financially

profitable type of heating

Safety

If any faults or failures are found, they must be repaired as soon as possible by a boiler engineer. Flue pipes,

ventilation ducts, air holes etc. must not be closed off or blocked. Flammable liquids or combustible

substances must not be placed in dangerous proximity to the boiler.

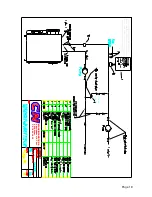

For systems with an operational pressure above 0.5 bar over pressure (closed system with pressure

expansion or open system where the height from the boiler to the highest water surface is more than 5

meter), the boiler must be equipped with a cooling spiral connected to a cold water supply.

Boilers equipped with a cooling spiral must not be used (should be switched off) if the water supply is out of

order, or the water supply to the boiler is shut off (e.g. on the main tap).

Startup, manual stoking

1. Fill the boiler with the required amount of combustible material.

2. Light the fuel from below.

3. Adjust the air supply hatches (only until the right air supply level is found) only during manual stoking

without stoker.

•

Note.

Be very careful when opening the door to the boiler during operation due to extreme heat

inside the boiler and smoke emission.

Stop:

When the fuel material has been burned, the heat supply from the boiler stops.

Summary of Contents for 120

Page 17: ...Page 17 ...