Page 7

Safety hose open systems (open expansion)

•

All the system boilers must have a connection to the atmosphere through a safety hose which cannot

be blocked.

•

Safety hoses must depart from the top of the system boiler(s). They must run at an uphill gradient to

the open expansion vessel and from there run at a steady downhill gradient, at a suitable distance

from a drain and in such a way that the outlet of hot water does not result in a risk of injury. The outlet

point must be cut at an angle.

•

At the highest point of the safety hose there must be an internal diameter of minimum 15 mm as a

siphon break.

•

The vertical distance from the highest point of the system to the boiler must not exceed 10 meters.

•

The total length of the safety hose must not exceed 20 meters.

•

For boilers > 60 kW the safety hose must have a minimum internal diameter of 35.5 mm

•

All pipes must be approved for 120 °C and minimum 10 bar over pressure.

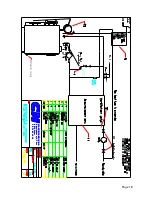

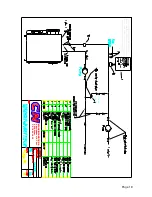

For installation with operational pressure >0.5 bar and open expansion principle diagram pages

17 & 20 must be used

•

If the operational pressure of the boiler exceeds 0.5 bar over pressure, the boiler unit (the installed

boiler including fittings and safety equipment) is covered by the Pressure Equipment Directive

97/23/EEC ”Installation of pressurised equipment”, which requires that the boiler unit must fulfil

certain essential safety requirements regarding the safety equipment of the boiler etc.

The boiler

must be fitted with a cooling spiral

•

Expansion vessel

: The vessel must be installed in accordance with the directions of The Health and

Safety at Work Act 1974.

•

The bottom of the expansion vessel should be installed only above pipes/radiator of the central

heating system and with an open expansion vessel. Block valves must under no circumstances be

placed between the boiler and the expansion vessel.

There must under no circumstances be any

circulation in the expansion vessel.

The boiler must be installed with pos. nos. 1, 2, 3, 4, 5, 7, 9, 10, 13 (drawings pages 17 & 20)

Description

Type / Requirements

Draw. Pos no. Supplier

Shunt valve

TA type TRV 300

1

CN (supplied)

Oper. thermostat

BC components type NTC-2322

2

CN (supplied with stoker)

Overheat. thermostat

Honeywell type L6188

3

CN (supplied with stoker)

Boiler thermometer

0-120 degrees

4

Installation engineer

Pressure gauge

(manometer)

0-3 maximum 5 bar, red mark at 2.5 bar

4

Installation engineer

Expansion vessel

CE labeled, minimum 8 % of total system

water volume

5

Installation engineer

Safety valve

CE approved

2 pces., 2.5 bar, clearance minimum 20 mm

7

Installation engineer

Cooling spiral

CN80:

Wieland heat exchanger type WRK 13

9

CN (supplied)

Cooling spiral

CN120:

Wieland heat exchanger type WRK 13

9

Safety thermostat

Honeywell type TS130, CE approved

10

CN

Water shortage protection RT 200 Pressostat

13

Installation engineer

Summary of Contents for 120

Page 17: ...Page 17 ...