Page 9

110

5,2

120

6,0

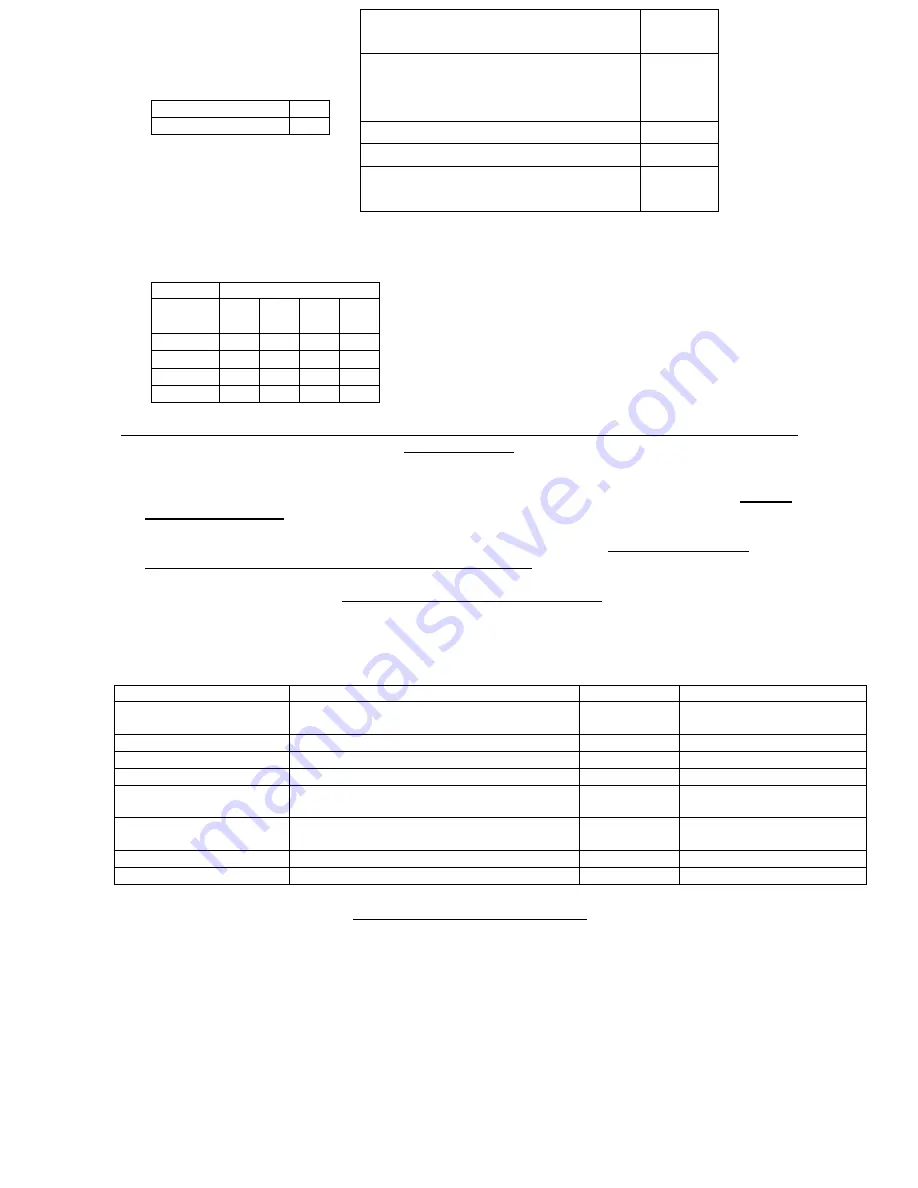

Expansion vessel efficiency

Example of calculation (new systems)

in % after initial and operational pressure

Oper. pressure bar

In.

pres.

1.0

1.5

2.0

2.5

0.5

25

40

50

57

1.0

20

33

42

1.5

16

28

2.0

14

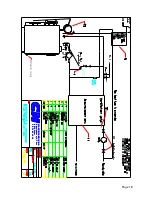

For boilers with open expansion and operational pressure < 0.5 bar, the principle diagram pages 18 &

21 must be used

If the operational pressure of the boiler is below 0.5 bar, the boiler must be installed in accordance with

the directions of The Health and Safety at Work Act 1974 about combustion hot water systems.

Cooling

spiral is not required

.

The bottom of the expansion vessel should be installed above the highest

pipe/radiator of the central heating system and with an open expansion vessel. Block valves must under

no circumstances be placed between the boiler and the expansion vessel.

There must under no

circumstances be any circulation in the expansion vessel.

Size of expansion vessel open system:

The expansion vessel must be at least 8 % of water content ( rese pipes and radiators)

acc. to Btv32.

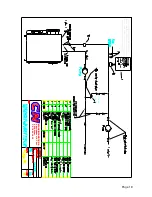

Boilers exclusively used for manual stoking must be installed with following pos. nos. 1, 4, 5, 11, 12

(draw. page 18)

Boilers used with stoker pos. nos. 1, 2, 3, 4, 5 (draw. page 21)

Description

Type / Requirements

Draw. Pos no. Supplier

Expansion vessel

CE labeled, minimum 8 % of total system

water volume

5

Installation engineer

Oper. thermostat

BS components type 2322

2

CN (supplied with stoker)

Overheat. thermostat

Honeywell type L6188

3

CN (supplied with stoker)

Boiler thermometer

0-120 C° degrees

4

Installation engineer

Pressure gauge

(manometer)

0-3 maximum 5 bar, red mark at 2.5 bar

4

Installation engineer

Accumulation tank

Type approved in acc. with ”Declaration on

Installation of Pressurised Equipment”

11

Installation engineer

Shunt valve

TA type TRV 300

1

CN (supplied)

Flue regulator

1” Robust

12

Installation engineer

Testing the safety equipment

.

The engineer must test the safety equipment before the unit is handed over to the user.

•

The engineer must check that the operation thermostat is working.

•

The engineer must also check the overheating protection.

This is done by removing the overheating thermostat from the dip pipe and placing it in boiling water.

The thermostat should now cut out and the system stop. Reset the thermostat once the temperature

has fallen, and place it back in the dip pipe.

•

The engineer must also check that the safety valves open at max 2.5 bar.

•

The engineer must test the operation of the thermal valve for the cooling spiral. The valve should

open at a sensor temperature of maximum 95 °C. Remove the sensor from the dip pipe and place it

in boiling water. Check that water now flows through the cooling spiral. Replace the sensor in the dip

pipe.

Maximum system temperature °C

90 °C

Water content heating system

Boiler (type 25) 180 L.

Installation 350 L.

530 L.

Water exp. (530x3,6/100)

19.08

Expansion vessel efficiency

57 %

Size expansion vessel

(19.08x100/57)=33.47=

34 L.

Summary of Contents for 120

Page 17: ...Page 17 ...