Model SH-2012AH-QG

Cutting Machine

(

C002

)

7

This key is used to reminder input of kerf compensating width; if no necessary to compensate(usually in

blanking), simply enter 0.

3.2.6[F6] ASSI

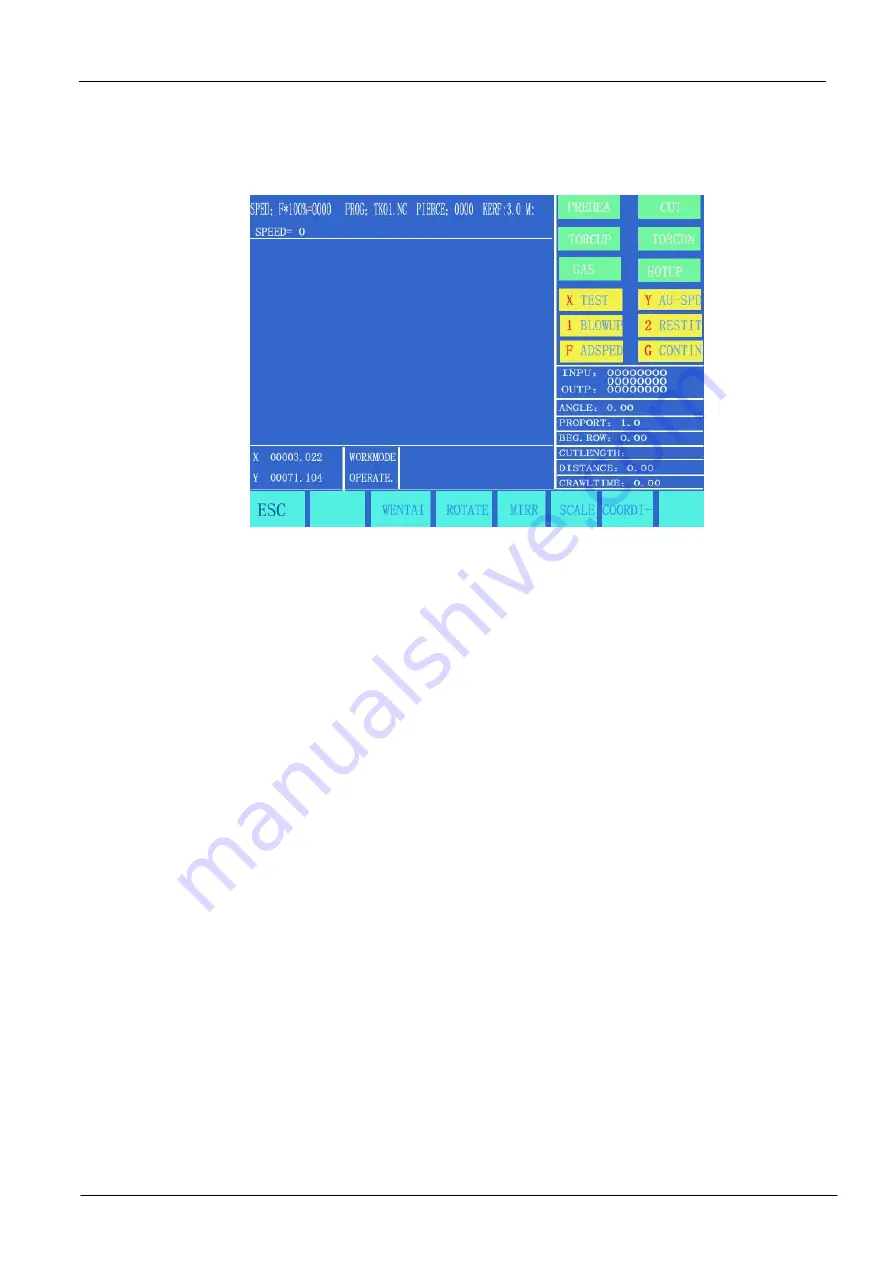

This key is used to enter the next lower level of menu, as shown in Fig. 3.2 below.

3.2.7. [F3] ROTATE(steel plate correcting feature)

3.2.7.1Machining at rotation angle

This feature is used when the steel plate is not positioned perfectly or the steel plate needs to rotate an angle

before machining. It is allowed to use

Rotate

function along with

BEG. PT.

and

END PT.

in

Manual

mode or

input the expected angle directly. After acknowledged, the system will start the machining program at the

appointed rotation angle.

Note: Counterclockwise direction is taken as positive angle.

3.2.7.2Example

The system is able to identify and calculate the rotation angle by measuring the origin point and the end point

of an edge of steel plate(a straight line). The procedure is as follows:

1)

Determine the datum line. Take one borderline of steel plate as baseline and move the cutting torch to the

origin point of this baseline. Press [F2] to set the beginning point of measurement.

2)

Control the cutting torch and let it move along the baseline to the end point. The larger distance between

the beginning point and the end point, the more accurate of the measurement. Aim the cutting torch at the

baseline and press [F3] to set the end point of measurement.

3)

At this moment, the rotation angle of the datum line is calculated. After the rotate function is fulfiled, the

rotation angle will appear in the OPERATE field, as shown in Fig. 3.2 below.

3.2.8[F4] MIRR

It is possible to select

X Mirror

,

Y Mirror

and

No Mirror

if press [F5] key continually. When X Mirror is

selected, the machining program will run along the symmetry direction of X-axis, as appears inverted

horizontally.

When Y Mirror is selected, the machining program will run along the symmetry direction of Y-axis, as appears

inverted vertically. When default No Mirror is selected, the machining program will run normally.

Fig. 3.2 ASSI window

www.collectcnc.com