TECHNICAL SPECIFICATION

TITLE:

IEC INSTALLATION INSTRUCTION

MANUAL FOR THE CRYSTALLINE

SOLAR PHOTOVOLTAIC MODULE

SPEC. NO.:

CNPV-PS-M-S0010-IEC

REVISION: J

EFFECTIVE DATE:

July 2012

AUTHOR(S):

Bypina Veerraju Chaudary, Yang Xiaowu

Page 3 of 15

CNPV Dongying Solar Power Company Limited,

Shengli Industry Park, Dongying City, Shandong Province 257000, PRC

http//www.cnpv-power.com E-mail:

marketing@cnpv-power.com

Tel: +86-546-7795555, Fax: +86-546-7795777

8. MOUNTING AND NOTES

Systems should be installed by qualified personnel only. It involves electricity, and can be dangerous if the personnel

are not familiar with the appropriate safety procedures.

The Module frame is made of anodized aluminum, and therefore corrosion can occur if the Module is subject to a

salt water environment with contact to a rack of another type of metal (Electrolysis Corrosion). If required, PVC or

stainless steel washers can be placed between the SPV Module frame and support structure to prevent this type of

corrosion. Module support structures that are to be used to support SPV Modules at correct tilt angles should be wind

and snow load rated for use by the appropriate local and civil codes prior to installation.

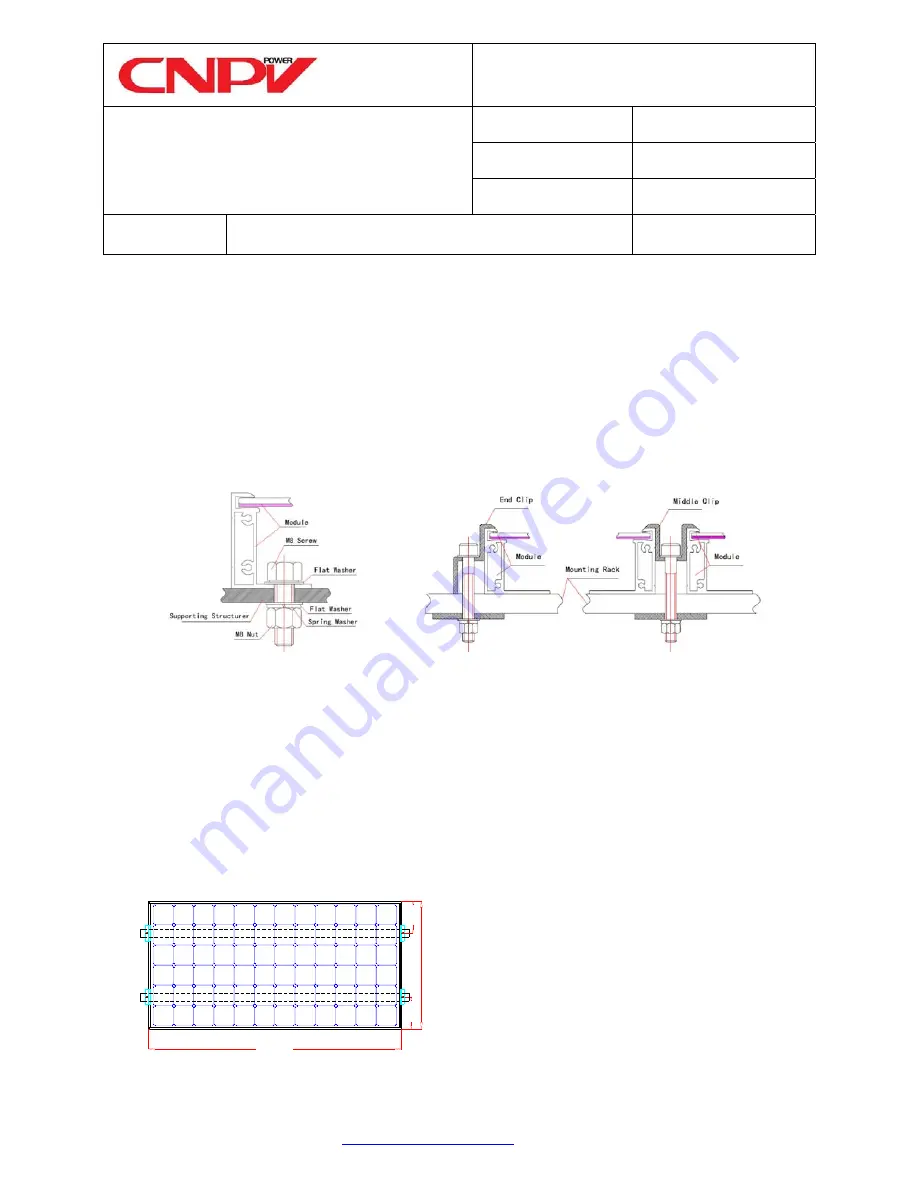

CNPV SPV Modules can be mounted as following method:

Figure 2 Mounting Method a and b

a)

Using corrosion-proof screws (M8) on the existing installing holes (see drawing 1, 3, 5 & 7) in the Module

frame. The frame of each Module has 4 or 8 mounting holes (12mm×9mm) used to secure the Modules to

supporting structure. The Module frame must be attached to a supporting rack using M8 stainless steel hardware

together with spring washers and flat washers in four places symmetrical on the SPV Module. See method a of

figure 2. The applied torque is about 8 Newton-meters.

b)

Using suitable Module clamps on the Module frame, see method b of figure 2. The module frame must be

attached to supporting rack using M8 stainless steel hardware together with corrosion-proof clips in four places

on the SPV module. See drawing 10, 12, 14 & 16,

with clamping clip,

for positioning of clamping clips. The

applied torque is about 8 Newton-meters. See figure 3 if clamping mounting is on short frames of the module.

W

idth

1/

4W

1/4

W

Length

c)

Insertion System

Method a: Using corrosion-proof

screws on existing Installation

Method b. Using suitable module

clamps on the module frame

Using Short sides for module clamping. W

means module width, and 1/4W means

permissible clamping range.

Figure 3. Mounting on short frames.