2

COMPOST BIN CONSTRUCTION

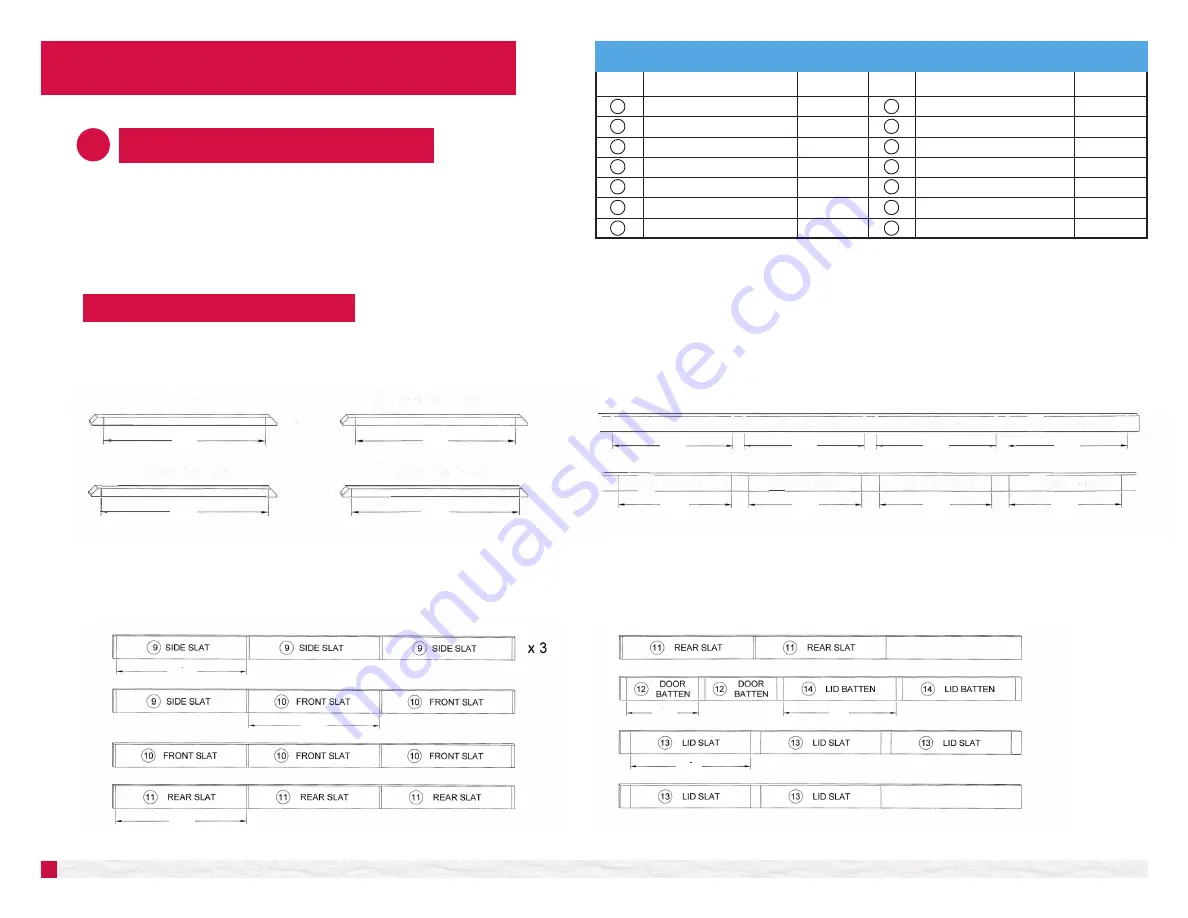

The Cutting Diagrams show how each piece of lumber is to be broken down.

The components are numbered in the order they are assembled. Due to the

moisture that is required for composting, it is highly recommended that all

cuts be treated with an end cut wood preservative.

2x2 Pressure Treated Baluster

Twelve (12) boards 36"long are required for components #1, 6, 7, 8.

1x6 Pressure Treated Lumber

Ten (10) boards 8' long are required for the following components #9 – 14.

2x4 Pressure Treated Lumber

Two (2) boards 10'long are required for components #2 – 5.

CUTTING THE COMPONENTS

1

CUTTING DIAGRAMS

�

�

Cutting

.

Diagrams

2x2 Pressure Treated Baluster

Twelve (12) boards

36"1ong

are required for components

G) ,

@ ,

(J),

® .

CD LEG

®

BASE TRIM SIDE

x8

31½"

31½"

(j)

BASE TRIM REAR

®

BASE TRIM FRONT

32¾"

32¾"

2x4 Pressure Treated Lumber

Two (2) boards

1

O' long

are required for components

(l) -

®.

I

0

FRONT RAIL

I

I

26¾"

0

SIDE RAIL

25½"

G)

REAR RAIL

26¾"

0

SIDE RAIL

25½"

I I

G)

REAR RAIL

I

26¾"

0

SIDE RAIL

25½"

x2

I

®

THRESHOLD

I

26¾"

0

SIDE RAIL

25½"

I

]

�

�

Cutting

.

Diagrams

2x2 Pressure Treated Baluster

Twelve (12) boards

36"1ong

are required for components

G) ,

@ ,

(J),

® .

CD LEG

®

BASE TRIM SIDE

x8

31½"

31½"

(j)

BASE TRIM REAR

®

BASE TRIM FRONT

32¾"

32¾"

2x4 Pressure Treated Lumber

Two (2) boards

1

O' long

are required for components

(l) -

®.

I

0

FRONT RAIL

I

I

26¾"

0

SIDE RAIL

25½"

G)

REAR RAIL

26¾"

0

SIDE RAIL

25½"

I I

G)

REAR RAIL

I

26¾"

0

SIDE RAIL

25½"

x2

I

®

THRESHOLD

I

26¾"

0

SIDE RAIL

25½"

I

]

�

�

Cutting

.

Diagrams

2x2 Pressure Treated Baluster

Twelve (12) boards

36"1ong

are required for components

G) ,

@ ,

(J),

® .

CD LEG

®

BASE TRIM SIDE

x8

31½"

31½"

(j)

BASE TRIM REAR

®

BASE TRIM FRONT

32¾"

32¾"

2x4 Pressure Treated Lumber

Two (2) boards

1

O' long

are required for components

(l) -

®.

I

0

FRONT RAIL

I

I

26¾"

0

SIDE RAIL

25½"

G)

REAR RAIL

26¾"

0

SIDE RAIL

25½"

I I

G)

REAR RAIL

I

26¾"

0

SIDE RAIL

25½"

x2

I

®

THRESHOLD

I

26¾"

0

SIDE RAIL

25½"

I

]

COMPONENTS LIST

#

Component Name

Quantity

#

Component Name

Quantity

1

Leg

8

Base Trim Front

1

2

Front Rail

1

Side Slat

10

3

Rear Rail

2

Front Slat

5

Side Rail

4

Rear Slat

5

Threhold

1

Door Batten

2

Base Trim Side

2

Lid Slat

5

Base Trim Rear

1

Lid Batten

2

10

9

8

3

6

13

7

14

2

5

12

1

4

11

32¾"

31½"

31

1

/

8

"

25

1

/

8

"

31

1

/

8

"

25

1

/

8

"

25

1

/

8

"

25

1

/

8

"

32¾"

31¼"

28¾"

17¼"

27"

31¼"

26¾"

26¾"

26¾"

26¾"