23

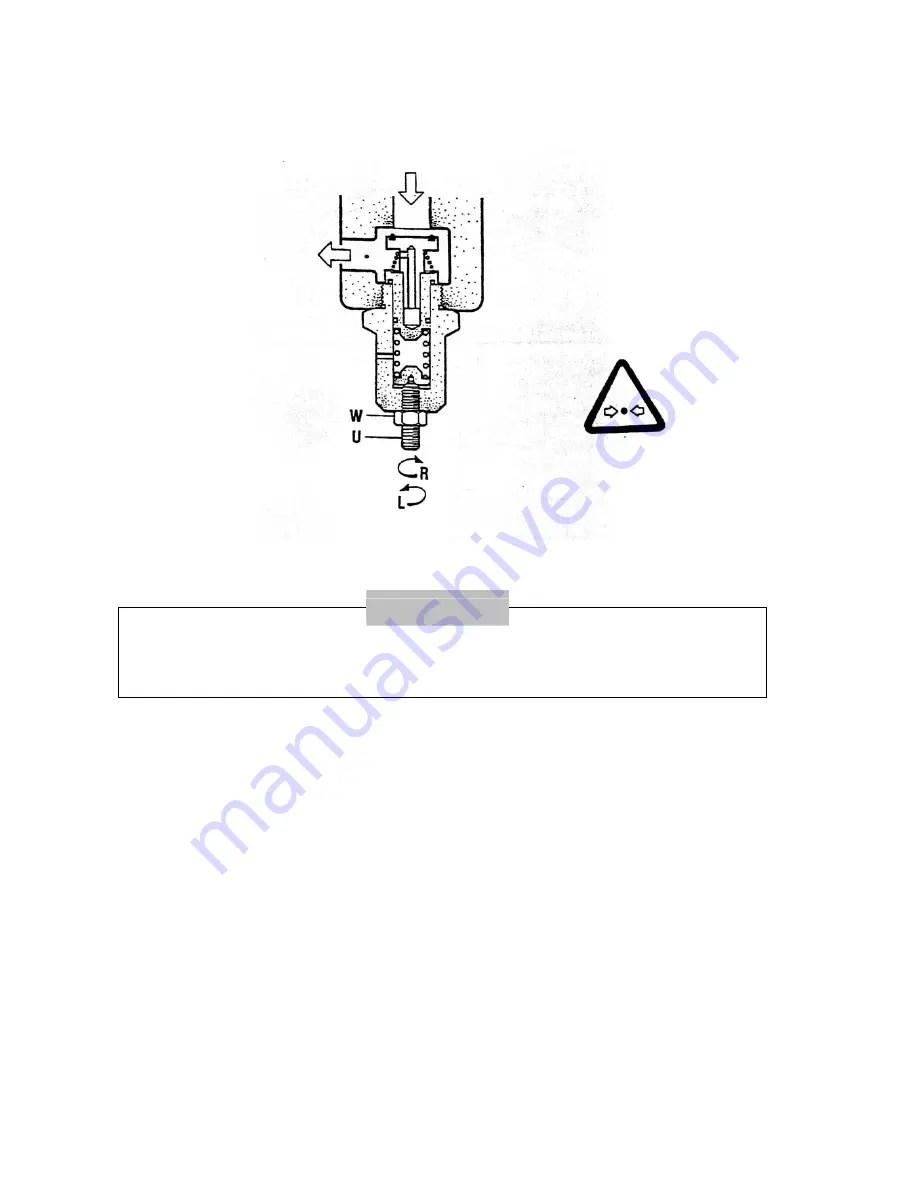

WARNING

The correct minimum pressure is vital for the function of the compressor. Tampering with the

adjustment may cause a compressor breakdown. Valves should be adjusted by authorized personnel.

Contact your distributor.

6-6. SUCTION CONTROL VALVE.

Service the suction control valve every 6,000 hours of operation or yearly

whichever comes first. Proceed as follows :

Stop the unit and disconnect the electrical mains

⒜

. Close the isolation stop valve.

Make sure that the unit is completely depressurized.

⒝

Remove the suction filter and silencer. Disconnect all the piping on suction control valve.

⒞

Remove the bolts fixing the suction control valve with air

⒟

-end. Take out the suction control valve with care

not to damage the surrounding equipment. Protect the air-end inlet against the entry of dust by covering

it.

Disassemble the suction control valve. Remove the gasket(or o

⒠

-ring) from groove. Use care so the gasket

surface or the groove is not damaged.

Inspect the Butterfly valve and non

⒡

-return valve for any damage or scratches.

Mount the suction control valve on the air

⒢

-end. Tighten the bolts and set screws.

Reconnect all the piping. Make sure that the installati

⒣

on positions are correct.

Open the isolation stop valve and start the unit. Make sure that the suction control valve is operating

⒤

correctly.

6-7. OIL /AFTER COOLER & COOLING FAN

.

It is important to keep the fins of oil cooler and after cooler free

from dust accumulation to ensure optimum efficiency of heat exchange. Therefore, the coolers and cooling fan

should be cleaned every 3,000 hours or six(6) month whichever comes first. To clean the cooler fins, use an air

nozzle or steam jettier. Wipe the accumulated dust off the cooling fan to prevent unbalanced rotation.(Extreme

environments may require more frequent servicing.)

Summary of Contents for CHSA-10M

Page 31: ...27 AIR END NK40 ...

Page 33: ...29 AIR END NK60 ...

Page 34: ...30 Appendix B 1 PART LIST FOR MODEL CHSA 7 5M 1 2 ...

Page 35: ...31 1 PART LIST FOR MODEL CHSA 7 5M 2 2 ...

Page 36: ...32 2 PART LIST FOR MODEL CHSA 10M 1 2 ...

Page 37: ...33 2 PART LIST FOR MODEL CHSA 10M 2 2 3 PART LIST FOR MODEL CHSA 15M 1 2 ...

Page 38: ...34 3 PART LIST FOR MODEL CHSA 15M 2 2 ...

Page 39: ...35 4 PART LIST FOR MODEL CHSA 20M 1 2 ...

Page 40: ...36 ...

Page 41: ...37 4 PART LIST FOR MODEL CHSA 20M 2 2 ...

Page 42: ...38 C Wiring Diagram for Model CHSA 7 5 10 15 20M ...

Page 43: ...39 Appendix D 1 Outline Drawing for Model CHSA 7 5 10M ...