12

INSTALLATION

4.0 Installation

4-1 Inspection

When you receive the compressor please inspect it closely.

Upon delivery, carefully check the compressor for damage

during transportation.

If goods are received in damaged condition, it is important

that you notify the carrier and insist on a notation of loss or

damage across the freight bill.

[ Fig.4-1 ] Name plate

4-2 Handling

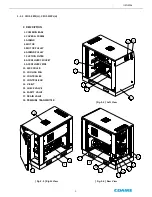

4-2-1 Handling by a forklift

When handling by a forklift, make sure that forks completely extend through the width of the unit. (Fig.4-2)

4-2-2 Handling by a shop crane

When handling by a shop crane, use the openings provided on common base where slings or steel wire

ropes can be use for lifting.

(Fig. 4-3)

[ Fig.4-2 ]

[ Fig.4-3 ]