33

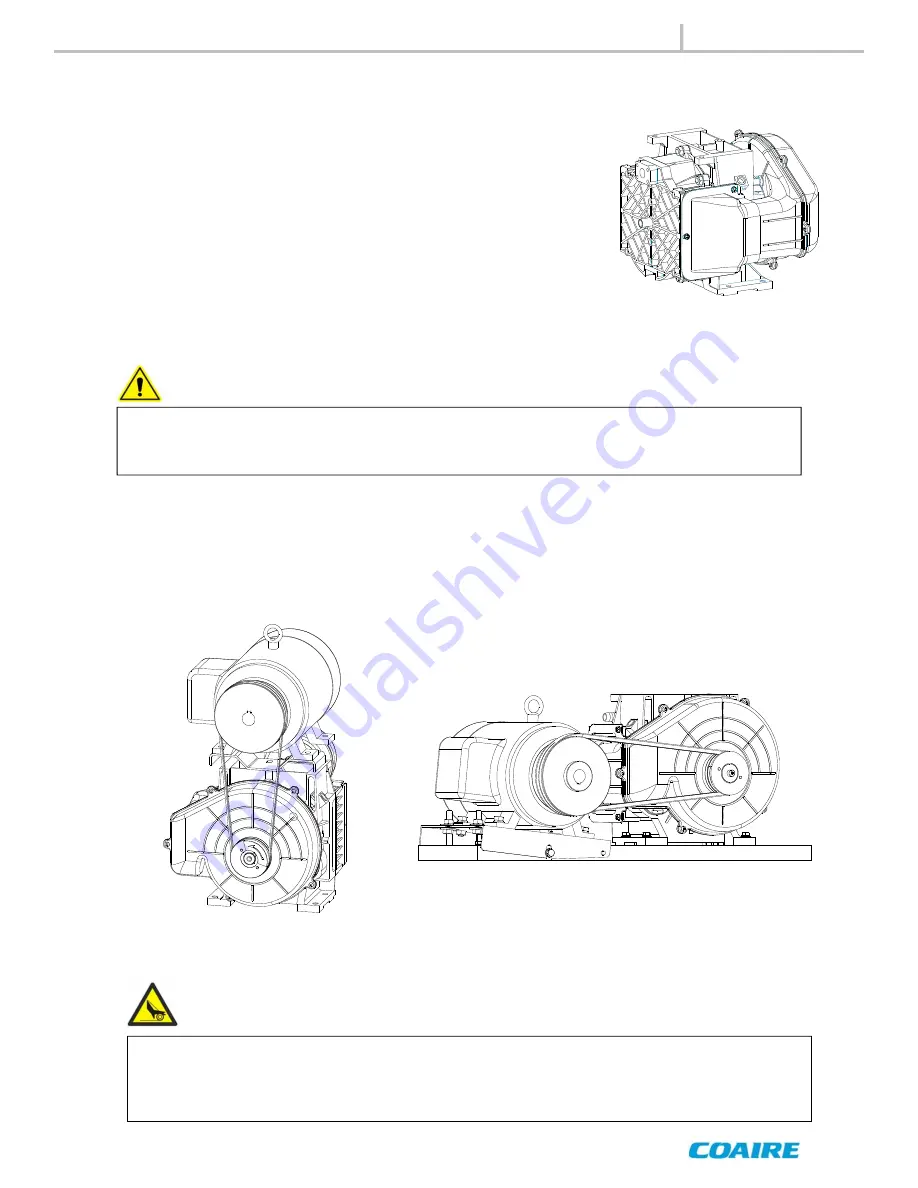

[ Fig.8-1 ] Scroll Airend

[ Fig.8-2 ] Vertical

(CSOF-M3PL(H), CSOF-M5PL(H))

[ Fig.8-3 ] Horizontal

(CSOF-S8PL(H), CSOF-S10PL(H))

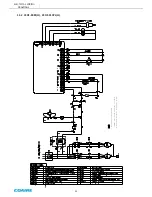

8-3 Maintenance

8-3-1 Regular Maintenance of the Airend

1) Check if there is any abnormal vibration or noise during a routine

operation, and contact the nearest distributor, if necessary.

2) There are two types of the scroll airend: Low Pressure (115 psi) and

High Pressure (140 psi). The maintenance period is different by

type specified in the identification plate attached on an airend. The

standard specification of Coaire airend is a low pressure type.

3) Periodically lubricate an airend with grease. See the maintenance

schedule for when the lubrication is needed.

The airend consists of precision parts, and needs special tool and jig for a repair and maintenance.

It shall only be disassembled by our qualified engineer. Contact the nearest distributor, if necessary.

Caution

8-3-2 Rotation of the Driving Part

If the motor is not started up or generates an abnormal noise, stop the compressor, turn the main

power off, and then manually rotate the motor pulley. If it does not rotate smoothly, contact the

nearest distributor for a service. It is mostly due to the damage on the motor bearing or when the

airend is stuck.

Warning

An air compressor is automatically operated. Do not come near the parts until the compressor is

stopped and the main power is turned off. It may cause a serious personal injury, if hair or clothes is

caught in the rotating parts.

MAINTENANCE