34

Model

New

Displace

P kg

δ in

P kg

δ in

3HP Vertical

1.5

0.2

1.3

0.2

5HP Vertical

1.7

0.2

1.6

0.2

3HP Horizontal

1.5

0.26

1.3

0.25

5HP Horizontal

1.7

0.24

1.6

0.23

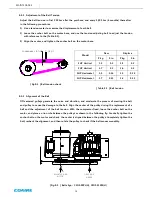

[ Table 8-1 ] Belt tension

Looseness = δ [in]

P [ kg ]

[ Fig8-4 ] Belt tension check

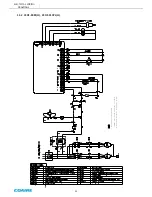

[ Fig.8-5 ] Belt align - CSOF-S8PL(H), CSOF-S10PL(H)

Adjust the belt tension in first 500 hrs after the purchase, and every 3,000 hrs (6 months) thereafter

in the following procedures.

8-3-3 Adjustment of the Belt Tension

1) Use a tension-meter to measure the displacement of each belt.

2) Loose the anchor bolt on the motor base, and use the tension adjusting bolt to adjust the tension

with reference to the [Table 8-1].

3) Align the motor, and tighten the anchor bolt on the motor base.

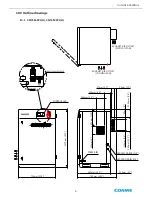

Off-centered pulleys generate the noise and vibration, and accelerate the process of wearing the belt

and pulley to cause the damage to the belt. Align the center of the pulley during the replacement of a

belt and the adjustment of the belt tension. With the compressor fixed, loose the anchor bolt on the

motor, and place an iron rule between the pulleys as shown in the following fig. Gradually tighten the

anchor bolt on the motor and check the center is aligned between the pulleys. Completely tighten the

bolt, recheck the alignment, and then rotate the pulley to check if the belt moves smoothly.

8-3-4 Alignment of the Belt

MAINTENANCE

FIXED SIDE

ADJUSTED SIDE

AIREND

MOTOR

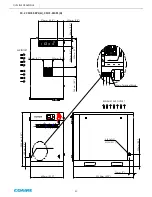

Be

lo

w

0

.0

4

in

c

h