Winkhaus locking systems are put through very stringent tests to meet the requirements of

today’s environment, including cycle testing.

The current requirement for PAS 23/24 is 50,000 full cycles of the door-set in order to simulate

10 years average use.

The requirement for maintenance is totally dependent on usage and environment, i.e. In areas

of high dust or corrosive atmospheres, the requirement for

lubrication will be more frequent than normal.

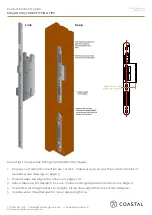

We therefore recommend that a light application of our GLS200

Lubricant Spray be used into the apertures of the hooks, dead-

bolt and latch and into both sides of the cylinder. In normal

usage Bi-annual application would be more than sufficient.

To prevent any damaging effect to the corrosion protection of

Winkhaus fittings, only PER neutral cleaning and care agents

should be used, which do not contain any abrasives.

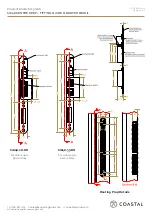

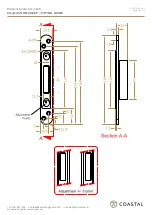

We also strongly recommend that the door set is checked over

for any movement, swelling or distortion of either sash or frame,

if necessary check for debris of any kind interfering with any of

the moving parts behind the mechanism itself. This operation

will require the mechanism to be removed and replaced by a

competent person. Any loose or missing fixing screws should be

tightened or replaced as required.

Under no circumstances should any aspect of the lock or

cylinder be tampered with in any way, as this may affect both

the serviceable life and guarantee.

Product Code: ML3120S

MAINTENANCE AND LUBRICATION GUIDE

LIT-DC-ML3120S

Page 13 of 14

T

01726 871 025

E

sales@coastal-group.com

W

coastal-group.com

© Coastal Specialist Ironmongery Ltd