17

O

N

13.3

TUBE TIRES

BEAD LOOSENING

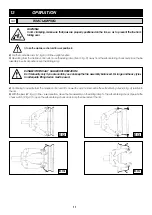

WARNING: Release inflation valve when deflating the tire so that the valve, falling inside the rim, is not an obstacle during bead loosening

Follow all the steps described previously for bead loosening tubeless tires.

With tube tires, however, stop disk movement as soon as the bead has loosened to avoid damaging the tube inflation valve.

DEMOUNTING

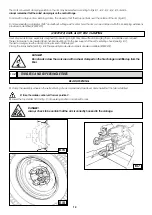

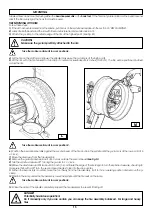

Take the mobile control unit to work position C.

1)

Tip the tool carrier arm

(14, Fig. D)

to its non-working position. Move it to the outside face of the tire and rehook it in this position.

2)

Rotate the tire assembly and at the same time move the hook tool

(18, Fig. D)

forward inserting it between rim and bead until it is

anchored to the tool.

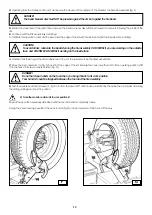

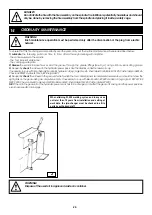

3)

Move the rim 1,5-2 inches (4-5 cm) from the tool taking care that it does not unhook from the bead.

4)

Move the hook tool towards the outside until the red reference dot is by the outside edge of the rim.

5)

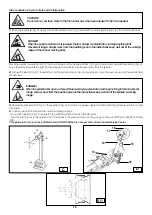

Insert lever

(see Fig. P) between rim and bead at the right side of the tool.

6)

Press down on the lever and lower the tire assembly to bring the edge of the rim about 1/4” (5 mm) from the hooked tool.

7)

Turn the tire counterclockwise pressing down on lever

until the bead is completely off.

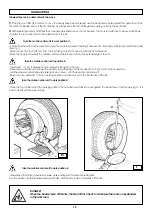

8)

Move the tool carrier arm to its non-working position. Lower the spindle until the tire is pressed down against the ramp. As the ramp is

moved slightly towards the outside, the tire will open a little and thus create enough space to remove the inner tube.

9)

Remove the inner tube and lift the tire back up.

Take the mobile control unit to work position B.

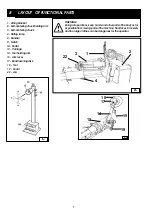

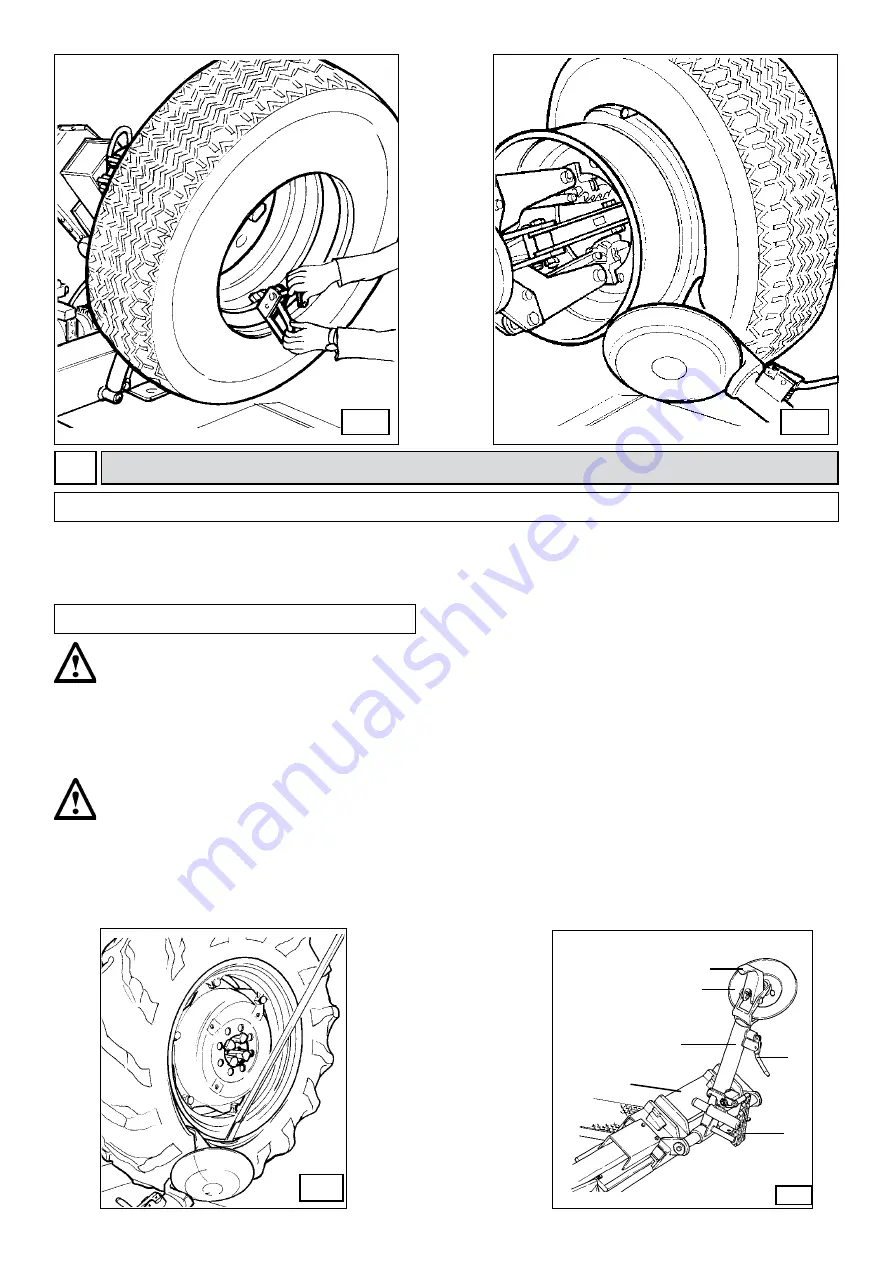

D

18

14

1

19

15

17

P