24 •

Important: Always read and follow the on-screen operating instructions.

V

Viid

de

eo

o B

Ba

alla

an

nc

ce

er

r

3.

Pull out and position the calibration sonar target

bracket to front of faceplate.

4.

Leave in position and close the hood.

Note:

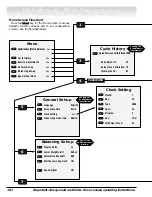

The target bracket, shown in calibration posi-

tion in figure 41, is used to allow the width sonar to

measure the distance to the balancer faceplate during

calibration.

Figure 41 - Sonar Target Bracket Positioned for Calibration

5.

Screen indicates “Reading Value”.

6.

Raise the hood and return the width sonar cali-

bration bracket to the stored position.

7.

Calibration accepted.

Note:

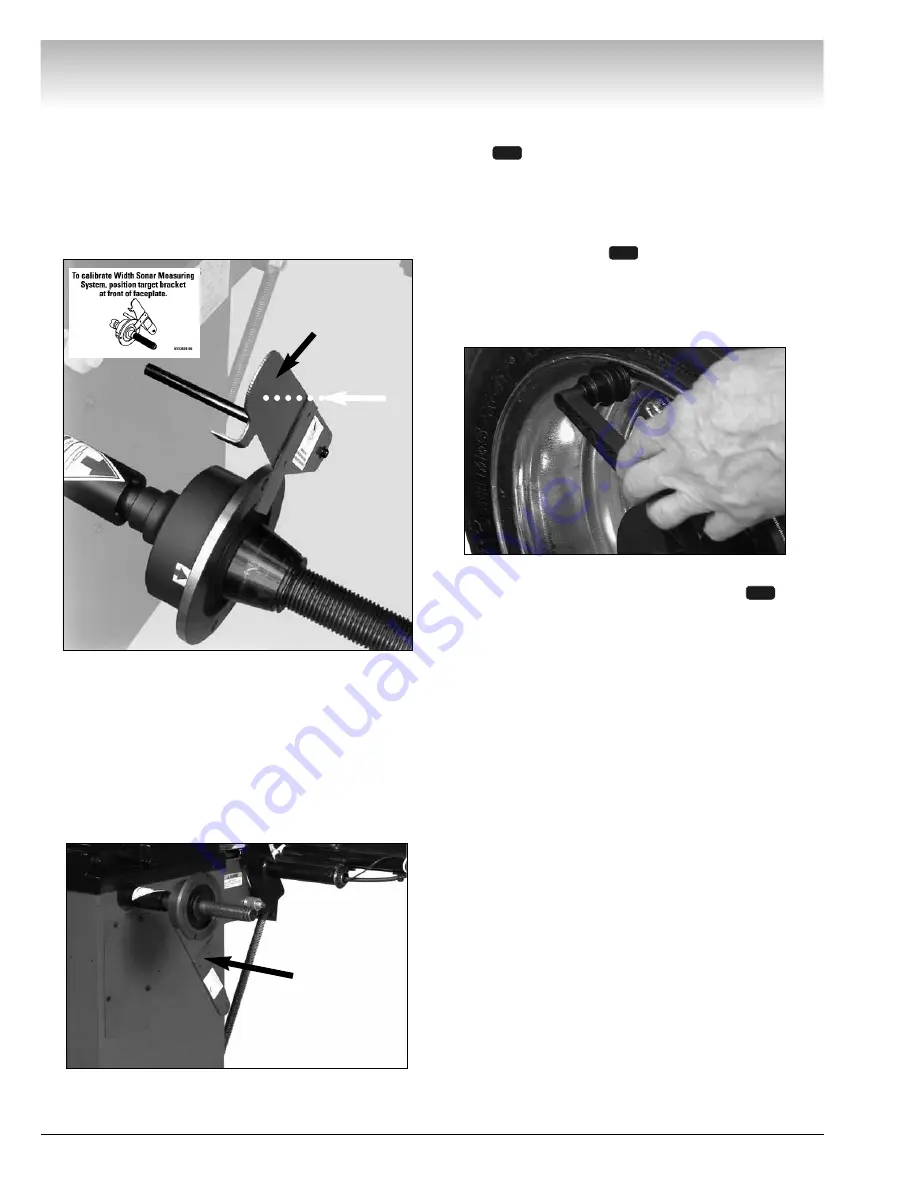

The sonar calibration target bracket is stored

flush with the side of cabinet at all other times, see fig-

ure 42.

Figure 42- Sonar Target Bracket in Stored Position

Diameter Arm Calibration -

Follow these instruc-

tions on-screen when calibrating the DIAMETER ARM

option :

1.

Mount a 14", 15", or 16" steel wheel with tire.

2.

Using the + or -, set the diameter to the same

diameter as rim.

3.

Press NEXT option

.

Note:

The diameter will display on the screen.

4.

Position offset arm at clip-on weight location on

wheel.

Figure 43 - Diameter Arm Calibration

5.

Hold at location and press NEXT option

.

6.

Screen indicates “Reading Value”.

7.

Return offset arm to home position.

8.

Calibration Accepted.

1

1

3

Sonar Target

Bracket

Sensor Target

Bracket in

Stored Position

Width

Sensor