15

Cobra Combi & Standard

© 2005 Atlas Copco Construction Tools AB

|

No 9800 0636 90

|

2005-09-16

Safety and operating instructions

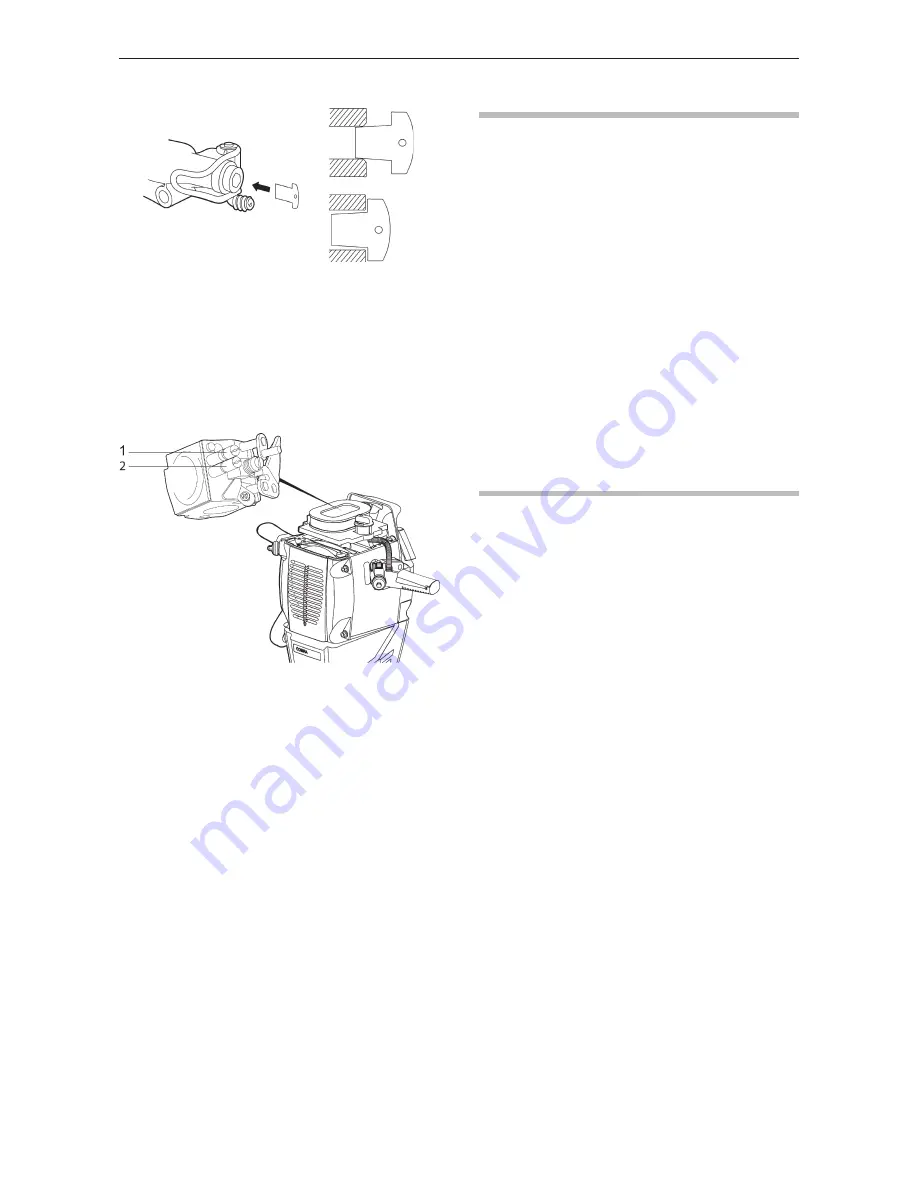

Tool chuck

If the chuck gauge provided can be inserted

fully across the flats of the hexagonal chuck, this

indicates that the chuck is worn out and must be

replaced.

Carburettor

On delivery the carburettor is adjusted and locked

so it meets EPA’s exhaust-gas standard.

The carburettor nozzle does not normally need to

be adjusted.

Normal setting:

Main nozzle (Cobra Combi Fe-cyl) (1) ........... 1,8 turns open

Idling nozzle (Cobra Combi Fe-cyl) (2) ........... 2,1 turns open

Main nozzle (1) ............................................... 2,0 turns open

Idling nozzle (2) .............................................. 2,0 turns open

When loaded, the maximum revs should be

2500–2650 rpm. The idling revs should be

1600–1800 rpm.

Trouble shooting

If the engine does not start, is difficult to start, runs

unevenly or has poor output, check the points

mentioned below (See image under "Main parts").

Check that the Stop button (See C under

"Starting and stopping") is in the ON position.

Check the fuel level.

Check the spark plug’s electrode distance.

Check that the air filter is not blocked.

Check that the fuel filter (See U under "Main

parts") is not blocked.

If the machine still does not work satisfactorily

following this procedure, please contact your

nearest authorised Atlas Copco workshop.

Scrapping worn-out

machines

Worn-out machines must be dealt with and

deposited in such a way that the maximum amount

of material can be recycled and the environment is

affected as little as possible.

Note:

Before a motor-driven drill is deposited

or thrown-away it must be emptied and

cleaned of petrol. Remaining petrol must

be dealt with in a way which not affects the

environment.

1.

2.

3.

4.

5.