17

4. DISASSEMBLING AND SERVICING

4.

DISASSEMBLING AND SERVICING

4-1

Troubleshooting

4-1-1

Starting Difficult

TROUBLE

CAUSE

REMEDY

N

or

m

al

c

yl

in

der

c

om

pr

es

si

o

n

N

or

m

al

s

pa

rk

pl

ug

sp

ar

k

Som

et

hi

ng

w

ro

ng

w

it

h

t

h

e

fu

el

s

yst

em

.

Fuel

s

up

pl

y

is

not

sm

o

ot

h

or

no

fuel

s

u

p

p

ly

.

There is no enough fuel in fuel tank and

fuel cock is closed.

Fill fuel, open fuel cock.

Air vent in the fuel filler cap is clogged

Dredge air vent.

Improper or clogged main oil flow hole.

Readjust or clean, blow to

get through.

Needle valve is not closed properly or

start hole is clogged.

Dismantle needle valve and

repair, clean, blow to get

through.

Float is damaged or sticking.

Repair float

Fuel

s

up

pl

y

is

n

or

m

al.

Fuel is too filthy or deteriorated

Replace

There is water in fuel.

Replace

Too much fuel in engine

Drain extra fuel, dry up spark

plug electrodes.

Wrong fuel brand

Select proper fuel brand

corresponding with the

requirements.

N

or

m

al

f

u

el

su

p

pl

y

s

yst

em

.

N

or

m

al

h

ig

h

–t

ensi

o

n

l

ine

spa

rk.

Spar

k pl

ug

i

s

in

bad

co

ndi

ti

o

ns

Too much carbon deposit and dirt around

electrodes.

Clear away.

Electrodes are burn damaged seriously

or insulators damaged.

Replace spark plug.

Improper electrodes gap.

Adjust to proper value.

H

ig

h

-t

en

si

o

n

l

in

e

no

sp

ar

k

N

or

m

al

s

pa

rk

pl

ug

High –tension line is damaged.

Replace

Ignition coil is damaged.

Replace

Magneto loses magnetism.

Replace

Abnormal gap between the ignition coil

and flywheel.

Adjust gap

Summary of Contents for Y173V

Page 4: ......

Page 8: ...2 DIMENSION AND TORQUE 4 2 DIMENSION AND TORQUE 2 1 Dimension ...

Page 48: ...46 4 DISASSEMBLING AND SERVICING INTAKE VALVE Reassembly ...

Page 64: ...4 DISASSEMBLING AND SERVICING 4 5 Electric Diagrams ...

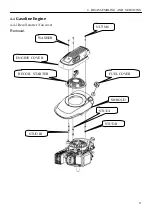

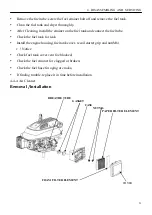

Page 65: ...61 appendix TRANSFORMATION POINTS Engine Cover SHROUD Recoil Starter ...

Page 66: ......