4. DISASSEMBLING AND SERVICING

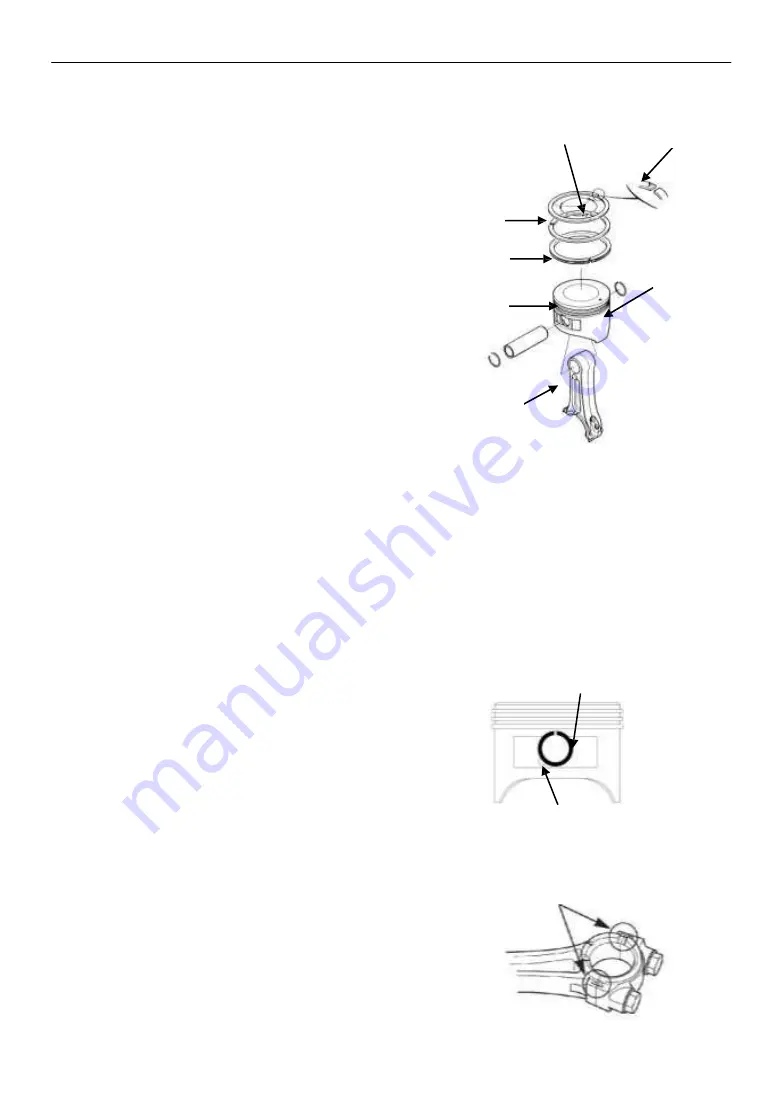

120°

MARKER

TOP

SECOND

“

▽

”MARK

OIL RING

CONNECTION ROD

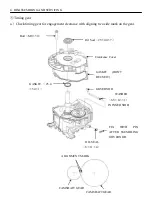

Reassembly

:

Make sure that the longer

end marked is toward the

piston head with the

“

▽

”

ALIGNMENT MARKS

①

Disassembly

:

a) Piston

Install with the maker mark

facing upward as shown. Do not

interchange the top ring and the

second ring (top ring with

chrome plated).

After assembly, check for

smooth movement of the piston

ring.

Stagger the piston ring end gaps

120° apart.

②

Reassembly

:

a)

Piston pin clip

Install by setting front end of the clip in the piston groove, holding the other end with

long nosed pliers, and rotating the clip in.

PISTON PIN CLIP

Do not align the end gap of the clip with the

cutout in the piston pin bore.

CUTOUT

b)

Connecting rod cap

Install by aligning the alignment marks on the

connecting rod cap.

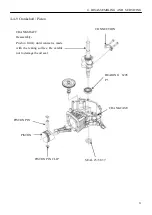

Summary of Contents for Y173V

Page 4: ......

Page 8: ...2 DIMENSION AND TORQUE 4 2 DIMENSION AND TORQUE 2 1 Dimension ...

Page 48: ...46 4 DISASSEMBLING AND SERVICING INTAKE VALVE Reassembly ...

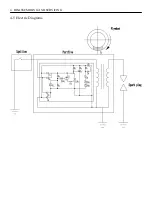

Page 64: ...4 DISASSEMBLING AND SERVICING 4 5 Electric Diagrams ...

Page 65: ...61 appendix TRANSFORMATION POINTS Engine Cover SHROUD Recoil Starter ...

Page 66: ......