EN

G

LI

S

H

7

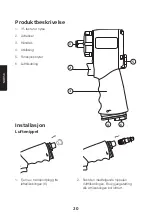

3. Fit a socket onto the anvil (1). Use

only undamaged impact sockets.

4. Connect the quick-connect coupling

of the air hose to the air inlet nipple on

the impact wrench.

Connection to the air supply system

a) This tool must only be connected to a clean, filtered and dry air supply which

provides an air pressure at the tool of 6.3 bar (90 psi).

Warning:

Too high a pressure

will reduce the lifespan of the tool and could cause serious personal injuries.

b) Connect the tool to the air supply using a hose designed for high pressure air.

c) Fit a quick-connect coupling in the air hose and a regular inlet nipple onto the impact

wrench. Do not attach a quick-connect coupling to the impact wrench itself, as this

would retain pressure in the tool even when the air hose has been disconnected.

d) In order for the tool to work at its full capacity, the air compressor must provide

the tool with at least the tool’s rated air consumption.

e) Only use air hoses of the recommended dimension and length. Do not connect

the tool to the air compressor without incorporating an easy to reach and operate

air cut-off valve.

f) Make sure that any water which has condensed in the tank of the air compressor

or the air hoses is emptied out regularly to prevent water being delivered into

the tool. Water in the system could freeze in the hose or cause the tool to rust.

Motor and impact mechanism lubrication

The motor and the impact mechanism are lubricated with grease

from the factory but might need to be lubricated further if the impact

is used daily. Add 4–5 drops of oil designed for air tools and

machines into the air coupling nipple on the impact wrench before

connecting the air hose. Repeat after every 3–4 hours of use.

Run the impact wrench for a few seconds under no load with

a rag over the exhaust port to catch any excess oil.