EN

G

LI

S

H

5

Lubrication

•

Note:

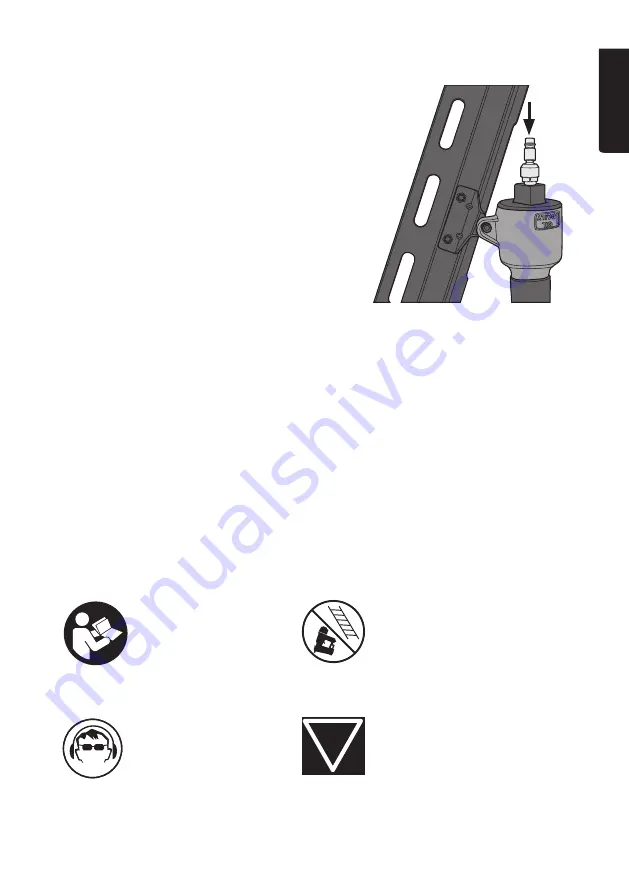

Lubricate with a few drops of oil in the air fitting

before using the tool for the first time.

• Regular but moderate lubrication is required for best

effect. Oil fed through the air fitting lubricates only

the trigger valve; the other internal components

are oiled at the factory and normally do not require

lubrication. Do not use flushing oil or additives since

such lubricants cause more rapid wear on the tool

packings and rubber cushion, which results in poorer

results and makes more care necessary.

• Pour some oil in the tool’s connecting nipple one

or two times daily. Only a few drops (1–2) of oil are

needed the first time. Too much oil merely clogs

the lines and is visible when air is released.

• Make sure that the magazine’s pusher moves

smoothly and not sluggishly by keeping it clean and

well-oiled. Also lubricate the impact pin itself with

a few drops of oil at every use.

Using in the cold

In cold weather near or below 0 °C moisture may freeze in the lines and cause the tool not to work

well. We recommend using an air lubricant or permanent antifreeze (ethylene glycol) as lubricant.

Note!

To prevent frost or ice forming in the tool’s valves and mechanisms, which can cause

the tool to malfunction, avoid storing the tool in a cold place.

Warning!

To prevent serious eye injury from flying nails and/or slivers the operator and others in the working

area must be equipped with eye protection that covers both the front and the sides when loading,

using or servicing the tool. Glasses without eye protection on the side and face masks do not

give adequate protection!

Warning symbols on tool

Read the instructions

for use.

The user and other persons

in the work area must use

protective glasses and

hearing protection.

The tool should not be used on

scaffolding or ladders. Do not use

the nail gun if the fastener could

shoot through something and hit

someone on the other side.

The gun is equipped with

a safety trigger.