EN

G

LI

S

H

9

1

4

2

3

5

3

1

2

4

Tightening the wheel nuts/bolts

Note:

When tightening wheel nuts/bolts, a torque bar (sold separately) with the

correct torque setting should be inserted between the impact wrench and the impact

socket, otherwise the nut/bolt might be overtightened and the wheel could be damaged.

1. Attach a hexagon impact socket which fits exactly onto the head of the screw/bolt

or nut which you want to undo.

2. Screw the wheel nuts/bolts in place by hand at least 3 complete turns in order to

prevent damaging the threads when they are tightened using the impact wrench.

3. Fit the socket fully over the nut/bolt you wish to tighten. Always start with the lower

nut/bolt (see below pictures).

4. Hold the impact wrench firmly with one hand around the front part of the tool, hold

the handle (7) with the other hand.

5. Press in the selector (6) for clockwise rotation of the socket (to tighten the bolt).

6. Lower the jack so that the vehicle is standing on the ground.

Warning:

Use a torque wrench to check that the wheels are fastened to

the recommended torque setting before using the car after changing its wheels.

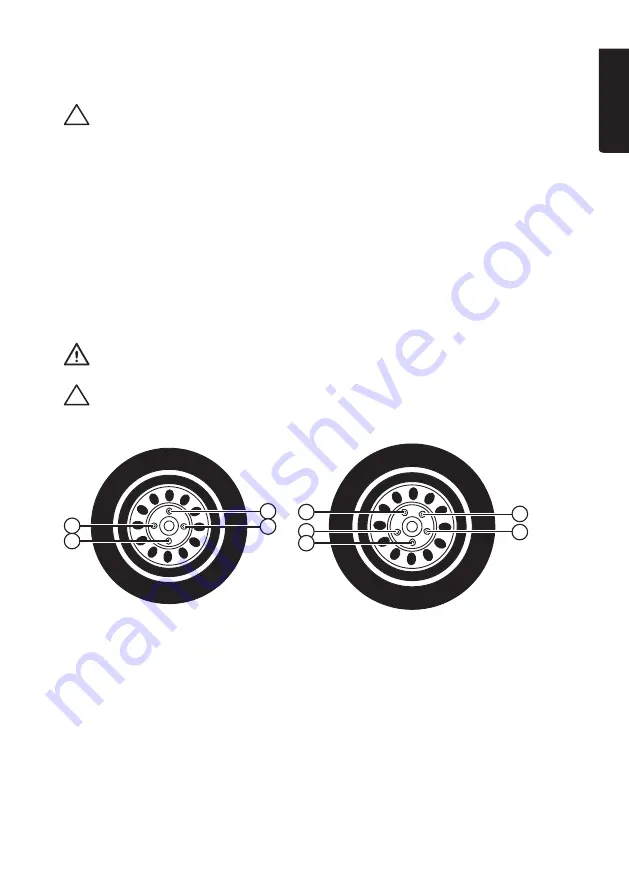

Note:

Tighten the wheel nuts/bolts in the correct order. Below is an example of

both a 4- and 5-bolt wheel setup.

Care and maintenance

• Clean the product by wiping it with a damp cloth. Use only mild cleaning agents,

never solvents or corrosive chemicals.

• Never attempt to repair or modify the product in any way. Repairs (and changing

the carbon brushes) must only be carried out by qualified service technicians.

Summary of Contents for 41-2375

Page 2: ......