EN

G

LI

S

H

7

Operating instructions

Preparations

Attaching the shoulder strap

Suitable coating materials

Water- and solvent-based paints, 2-component paints, primers, clear finishes, vehicle

finishes, glazes, wood preservatives (sealants, oils, etc), wood stains, insecticides and

certain flour paints such as Falu Vapen.

Unsuitable coating materials

Emulsion paints, alkaline paints, calcimine paints (whitewash), materials with

a flashpoint below 21 °C.

Preparing the coating material (thinning)

Thoroughly shake the can of coating material before opening it. Coatings such as paints

normally need to be diluted/thinned before spraying. Test a small amount of the coating

before diluting it all. Follow the manufacturer’s advice for thinning the coating you are

using. Ask your local paint shop for advice if you are unsure, explain that you are using

a HVLP (high volume, low pressure) type spray gun. The thickness of a paint is denoted

by its viscosity and is measured by letting a certain amount of paint run through a hole

of a certain diameter. The longer it takes for the paint to run through the hole, the higher

the viscosity. Viscosity is measured in seconds.

Warning:

Only use coating materials and solvents with a flashpoint above 21 °C.

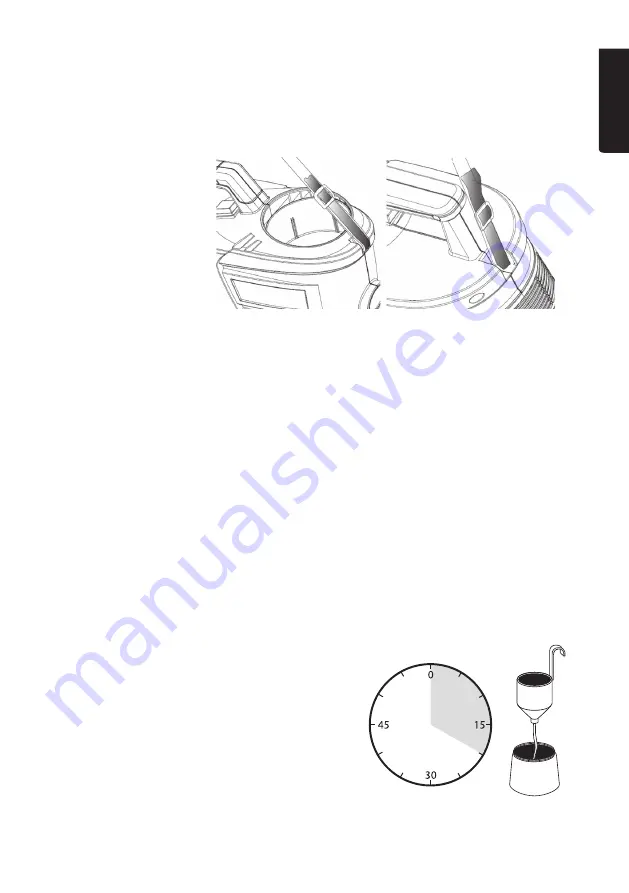

Fasten the shoulder

strap to the housing of

the air compressor and

adjust the length.

Measuring the viscosity:

1. Shake the container of paint before

performing a viscosity test.

2. Dip the entire viscosity cup into the coating

material so that it fills completely.

3. Hold up the viscosity cup and measure how

long it takes for the paint to run through the hole.

4. Dilute the paint if it is too thick and measure

it again.