WARNING!

SIREN PRODUCTS:

This equipment is intended for use by authorized personnel only. It is the user’s responsi-

bility to understand and obey all laws regarding emergency warning devices. The user

should check all applicable city, state and federal laws and regulations.

Public Safety Equipment, Inc., assumes no liability for any loss resulting from the use of

this warning device.

Proper installation is vital to the performance of the siren and the safe operation of the

emergency vehicle. It is important to recognize that the operator of the emergency vehicle

is under psychological and physiological stress caused by the emergency situation. The

siren system should be installed in such a manner as to: A) Not reduce the acoustical

performance of the system, B) Limit as much as practical the noise level in the passenger

compartment of the vehicle, C) Place the controls within convenient reach of the operator

so that he can operate the system without losing eye contact with the roadway.

Emergency warning devices often require high electrical voltages and/or currents. Prop-

erly protect and use caution around live electrical connections. Grounding or shorting of

electrical connections can cause high current arcing, which can cause personal injury and/

or severe vehicle damage, including fire.

PROPER INSTALLATION COMBINED WITH OPERATOR TRAINING IN THE PROPER

USE OF EMERGENCY WARNING DEVICES IS ESSENTIAL TO INSURE THE SAFETY

OF EMERGENCY PERSONNEL AND THE PUBLIC.

Unpacking and Preinstallation

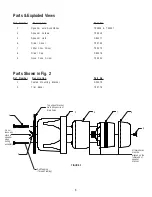

Carefully unpack the unit and check the contents against the parts list on page #6 of this booklet. Report any damage to carrier

immediately.

3

Installation and Mounting

!

WARNING!

!

Larger wires and tight connections will provide longer service life for components. For high

current wires it is highly recommended that terminal blocks or soldered connections be used

with shrink tubing to protect the connections. Do not use insulation displacement

connectors (e.g. 3M

®

Scotchlock type connectors). Route wiring using grommets and

sealant when passing through compartment walls. Minimize the number of splices to

reduce voltage drop. High ambient temperatures (e.g. underhood) will significantly reduce

the current carrying capacity of wires, fuses, and circuit breakers. Use "SXL" type wire in

engine compartment. All wiring should conform to the minimum wire size and other

recommendations of the manufacturer and be protected from moving parts and hot

surfaces. Looms, grommets, cable ties, and similar installation hardware should be used to

anchor and protect all wiring.

Fuses or circuit breakers should be located as close to the power takeoff points as possible

and properly sized to protect the wiring and devices.

Particular attention should be paid to the location and method of making electrical

connections and splices to protect these points from corrosion and loss of conductivity.

Ground terminations should only be made to substantial chassis components, preferably

directly to the vehicle battery.

The user should install a fuse sized to approximately 125% of the maximum Amp capacity

in the supply line to protect against short circuits. For example, a 30 Amp fuse should

carry a maximum of 24 Amps. DO NOT USE 1/4" DIAMETER GLASS FUSES AS THEY

ARE NOT SUITABLE FOR CONTINUOUS DUTY IN SIZES ABOVE 15 AMPS. Circuit

breakers are very sensitive to high temperatures and will "false trip" when mounted in hot

environments or operated close to their capacity.

Summary of Contents for FM100C

Page 7: ...NOTES ...