6

5

6

7

8

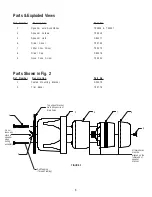

FIGURE 3

9

3

4

Top edge of bracket

must be opposite of

drain holes.

Do not

leave any

slack in

speaker

wires

during

assembly.

All drain holes

must be

alligned on the

lower end of

speaker

bracket.

Parts & Exploded Views

Parts Shown in Fig. 2

1

Coated Mounting Bracket

S 3 5 4 7 0

2

Trim Bezel

T 0 3 7 7 6

Ref Number

D e s c r i p t i o n

Part No.

3

Speaker wire Assemblies

T04346 & T04347

4

Speaker Screws

T 0 6 5 1 9

5

Speaker Horn

S 8 5 4 7 7

6

Driver Cover

T 0 3 7 3 9

7

100w Siren Driver

T 0 3 4 7 0

8

Driver Cap

S 8 5 4 7 8

9

Nose Cone Screw

T 0 9 2 0 4

Ref Number

D e s c r i p t i o n

Part No.

Self Tapping

(Thread Clearing)

Summary of Contents for FM100C

Page 7: ...NOTES ...