RECOMMENDATION FOR BRUSH SWEEPERS

SETTING THE SWEEPERS REQUIRES A

3/4”

WRENCH.

THE BRUSH HEAD SHOULD BE OFF THE GROUND AT MIDWAY IN ITS TRAVEL.

ALL SWEEPERS SHOULD PITCH FORWARD SO THAT THE PART OF THE SWEEPER

CLOSEST TO THE TIRE IS NOT MAKING CONTACT WITH THE GROUND.

THE HIGHER THE BRUSH IS SET WHILE STILL CLEARING A PATH FOR THE TIRE

THE LONGER THE LIFE OF THE BRUSH.

SETTING THE BRUSH TO LOW OR

“

PLOWING

”

THE BRUSH INTO THE GROUND WILL

DECREASE THE LIFE AND THE OVER ALL SPEED OF THE BRUSHES THUS LOSING

EFFECTIVENESS.

THE SWEEPER MOTORS RUN IN SERIES SO INCREASED RESISTANCE TO ROTA-

TION EFFECTS ALL SWEEPERS.

PERIODICALLY CHECK SWEEPERS FOR TRASH LIKE TREE ROPE THAT WILL WRAP

AROUND THE MOTOR SHAFT AND CAUSE THE SHAFT SEAL TO LEAK.

RECOMMENDATION FOR RUBBER FINGER SWEEPERS

RUBBER FINGERS SHOULD HAVE

1”

OF FLAT GROUND ENGAGEMENT ON FRONT

EDGE THAT CREATES A HALF MOON OF CONTACT TO CENTER OF SWEEPER.

HEIGHT ADJUSTMENT

ANGLE ADJUSTMENTS

FLAT NOT RECOMMENDED

OPTIMAL SETTING ANGLE

O

peration

14

RUBBER FINGER ADJUSTMENT EXAMPLE

Shaker operation tips

Summary of Contents for R Series

Page 1: ...OWNERS MANUAL COE S7 R SERIES SIDE MOUNT SHAKER VERSION 1 1 ...

Page 2: ......

Page 8: ...Operation 5 Cab OPERATORS CAB AREA DISPLAY JOYSTICK ...

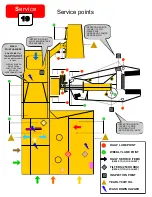

Page 30: ...Service 27 Component locations 40A 40A 40A 40A AC 60A RADIATOR 100A 200A AC RADIATOR ...

Page 44: ...Circuits 41 S7R electrical circuit ...

Page 45: ...Circuits 42 ...