5

There are 2 view modes to choose::

-

Pressure

: it is visualized “P LINE” (real pressure of the installation) and “SET P” (working programmed

pressure).

-

Service

: it is visualized “Hz” (working frequency of the inverter), “LINE” (input pressure chosen), “SET P”

(real pressure of the installation) y “FL” (flow sensor state).

The default value is 0,3 bar. This value of pressure is the one that the system will subtract to the input

pressure, resulting the final pressure to which the system will set in motion when the hydraulic network

have a demand. Using keys

p

q

to modify the initial value. It is recommended to maintain this value

between 0,3 and 0,6 bar. Example:

The value should be greater as much as smaller be the accumulation and vice versa.

“TIMER STOP” default value is 5”. This will be the employed time by the system in stopping once ceased the

consumption in all the installation. Using keys

p

q

we can modify the initial value.

If the installation does not have level probe press ENTER to validate NOT. If the installation has a level probe,

by mean of keys

p

q

we can change NO by YES.

Follow instructions of the previous step. See intensity value in A over the characteristics plate.

By mean of keys

p

q

enter the nominal intensity value in A of pump 1 enabling the thermal protection. This

value is located over the characteristics plate of the motor. Press ENTER for validation.

Using the START/STOP pushbutton corresponding pump 1 verify its rotation sense. By mean of keys

p

q

(0/1)

we can change it. Press ENTER for validation.

This screen is not available if we have selected single-phase pumps.

Using

p

we can increase the lower limit of the speed of rotation of the pump´s motors.

Proceed identically for pump 2.

By mean of

p

q

we can change the values and press

ENTER

for validation. Whenever we want to quit the configuration sequence

press

MENU.

After every

ENTER

it will appear automatically the different screens that constitute the sequence of configuration.

This will be the system working pressure. Use keys

p

q

for modify the initial value (2 bar).

WARNING! input pressure must be al less 1 bar lower than the maximum pressure of the pumps. Set

pressure must be under 12 bar.

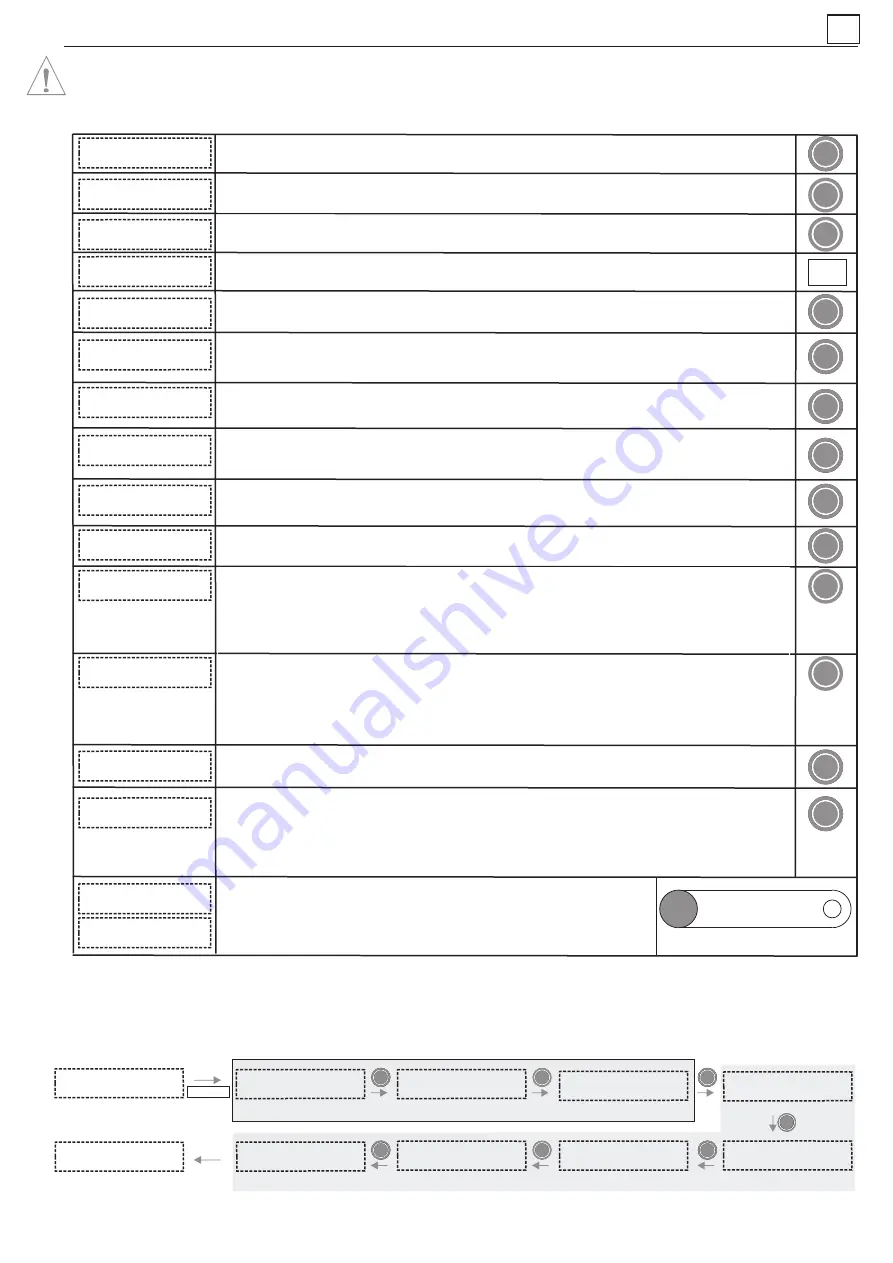

MENU

3"

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

3”

AUTOMATIC

Pushing simultaneously

MENU

+

p

during 3” we will get the register of functions and alarms, by mean of the pushbutton

ENTER

we are

able to advance inside the register, once we get the last register we can go back to the main menu pushing

ENTER

again. The

visualization sequence is as follows:

ALARM REGISTER

SHORTCIRC. 0

ALARM REGISTER

I MAX P1

0

ENTER

- Input pressure:

2 bar.

- Differential start:

0,3 bar.

- Final start pressure:

2 - 0,3 =

1,7 bar.

By mean of keys

p

q

we can choose the languages: “LANGUAGE ENGLISH”, “LANGUE

FRANÇAISE”, “LINGUA ITALIANA” e “IDIOMA ESPAÑOL”.

To start configuration sequence push MENU during 3”.

Being inside configuration menu we are having access to the phase of installation.

Being inside configuration menu we are having access to the phase of programming.

After pressing ENTER pushbutton, the system will remain configured showing the

type of view chosen in the previous section.

Press AUTOMATIC in order to quit manual mode.

ALARM REGISTER

TEMP.

0

ENTER

ENTER

ENTER

ENTER

FUNCTION REGISTER

CONNECTIONS

25

REGISTER OF FUNCTIONS AND ALARMS

ALARM REGISTER

I MAX. P2

0

ALARM REGISTER

NO WATER

ENTER

ENTER

FUNCTION REGISTER

HOURS 26 h

FUNCTION REGISTER

STARTS

32

Register of operational controls

Register of alarms

P LINE SET P

0,0 bar 0,0 bar

SET UP MENU

LANGUAGE ENGLISH

MAX. INT. PUMP 1

OFF

MAX. INT. PUMP 2

OFF

MIN. SPEED

15 Hz

ROTATION SENSE PUMP2

0

0 Hz

LEVEL PROBE

NO

PROGRAMMING MENU

SET PRESSURE

2,0 bar

DIF. START

0,3 bar

TIMER STOP

5 s

VIEW MODE

PRESSURE

ROTATION SENSE PUMP1

0

0 Hz

P LINE SET P

0,0 bar 0,0 bar

Hz LINE SET P FL

42 2,0 bar 2,0 1

P LINE SET P

0,0 bar 0,0

P LINE SET P

0,0 bar 0,0

MENU+

p

3

4

2

0

1

5

6

7

8

9

10

11

13

14

12

CONFIGURATION.

SPEEDMATIC ALT

EN