A thermal sensor in the body of the

iSpot S

protects the unit against overheating.

The thermal sensor operates by removing voltage to the lamp if the ambient temperature rises above a preset maximum due to either

less than ideal air circulation around the fixture or in the event of cooling fan failure.

Whilst every possible precaution has been taken to ensure the trouble-free operation of your

iSpot S

, the following periodic maintenance

is highly recommended.

To gain access to the internals of the unit refer to section

10.2. Opening up the projector housing

of this manual.

12.1. Periodic cleaning

Lenses and reflectors

Even a fine layer of dust can reduce the luminous output substantially. Regularly clean all lenses and the reflector using a soft cotton

cloth, dampened with a specialist lens cleaning solution.

Fans and air passages

The fans and air passages must be cleaned approximately every 6 weeks; the period for this periodic cleaning will depend, of course,

upon the conditions in which the projector is operating. Suitable instruments for performing this type of maintenance are a brush and

a common vacuum cleaner or an air compressor.

12.2. Periodic maintenance

Lamp

The lamp should be replaced if there is any observable damage or deformation due to heat. This will avoid the danger of the lamp

exploding.

Mechanicals

Periodically check all mechanical devices for wear and tear; gears, guides, belts, etc., replacing them if necessary. Periodically check the

lubrication of all components, particularly the parts subject to high temperatures. If necessary, lubricate with suitable lubricant, available

from your coemar distributor.

Electrical components

Check all electrical components for correct earthing and proper attachment of all connectors, refastening if necessary.

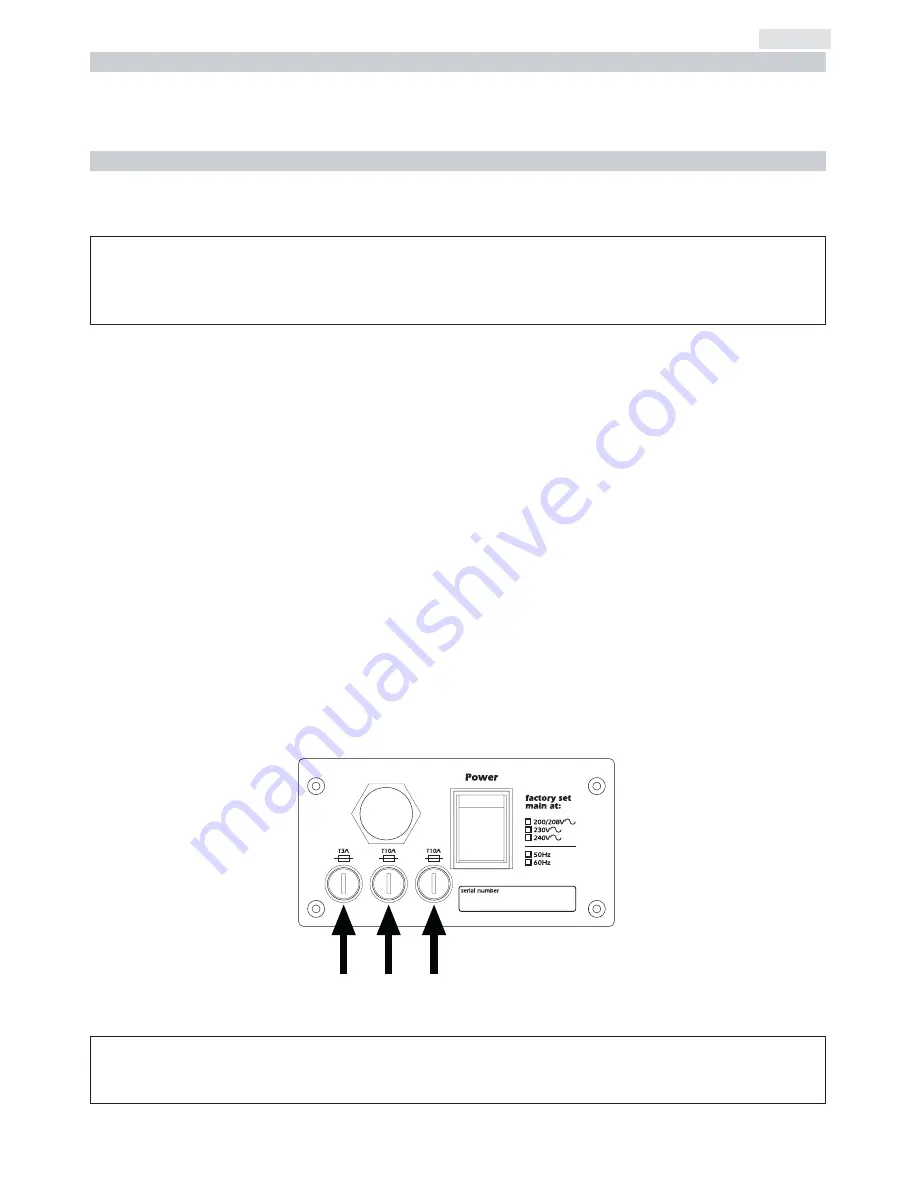

12.3. Fuse replacement

Locate the fuse, which protects the lamp and electronics, in the base of the

iSpot S

.

Using a multimeter, test the condition of the fuse, replacing it with one of equivalent type if necessary.

12.4. Electronic motor alignment

The display panel of the

iSpot S

allows for the electronic alignment of the projector’s motors in the optical system. This procedure is per-

ATTENTION!!

This procedure should only be undertaken by qualified and experienced technical personnel..

ATTENTION!!

Always remove mains power and ensure the unit is sufficiently cooled prior to opening up the housing.

12. Maintenance

11 Thermal protection

23

English