Summary of Contents for BRILLIANCE 3.0

Page 1: ...TM_EN Part No 1764040_03 BRILLIANCE 3 0 TECHNICAL MANUAL ...

Page 37: ...37 BRILLIANCE 3 0 ELECTRICAL DIAGRAM IO Board outputs ...

Page 38: ...38 BRILLIANCE 3 0 ELECTRICAL DIAGRAM Wiring sketch X 2 capacitor FA2 H8 ...

Page 40: ...40 BRILLIANCE 3 0 Water system rotary pump FLOW CHARTS ...

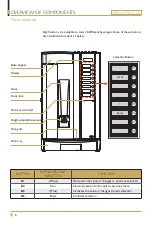

Page 45: ...45 BRILLIANCE 3 0 EXPLODEDVIEW Door Front Drawing 1 9 3 13 12 8 6 10 5 2 15 7 11 4 14 ...