10

Electrical Parts and Brake

1. Refer to Figures 14 and 15. Remove the cover to access the

controls. Single-phase models also have a starting switch and

capacitor mounted on the motor as shown in Figure 14. The

terminal blocks and end clamps snap off of the rails on the

plate using a small screwdriver. DO NOT SLIDE THE END

CLAMPS.

The contactor can be slid off the rail, but must be snapped on.

Where the contactor fits the rail, one side has springs or pads

that apply pressure against the edge of the rail. By pressing

against that side at the base of the contactor, you can snap

the part on or off using a rotating action. Note the numbers

that label the terminals on the contactor and orient the part as

shown in Figures 7A-7C. Single-phase contactors have a

small jumper that is not present on the 3-phase (note the 3

and 5 terminals on the reversing contactor in Figure 7A).

2. Remove the electrical panel by removing the stand-off

screws (See Figures 14 & 15). The limit switch and brake are

now accessible as shown in Figure 5.

3. Remove the transformer bolted to the back of the panel plate

if it requires replacement.

4. Refer to Figure 13 to disassemble the brake. See BRAKE

ADJUSTMENT on page 8 to properly set the brake.

5. Refer to Figure 16 to disassemble the limit switch. See

LIMIT SWITCH ADJUSTMENT on page 8 to properly set

the upper and lower limits of travel.

6. Refer to Figure 17 for repairs on the pushbutton station. Also

refer to the wiring diagram inside the electrical cover or

Figures 7A, 7B and 7C for wiring instructions.

Motor

Refer to Figures 11 and 12.

The lifting motor’s motor is located on the opposite end to that

of the electrical parts, but the two are tied together with

electrical leads running through the housing.

1. If it is necessary to replace or repair the motor,

DISCONNECT THE LIFTING MOTOR FROM THE POWER

SUPPLY and remove the electrical cover.

2. Loosen the screw clamps on the terminal blocks and

reversing contactor to disconnect the motor leads

(See Figures 14 and 15).

3. Remove the four motor mounting bolts attaching the motor

to the housing. It will come loose at the motor coupling.

4. Inspect the motor coupling, motor shaft and all the bearings.

Replace as necessary.

5. Install new or repaired motor according to the wiring diagram

located inside the electrical cover or Figures 7A, 7B and 7C.

Gearing

Use the Replacement Parts List for Basic Unit and Gearbox

Parts to help in repairs on gearing (See Figures 10 and 18). As

disassembly is extensive for gearing, disconnect the lifting

motor and move it to a workbench.

1. Remove electrical cover.

2. Remove electrical panel.

3. Remove brake assembly.

4. Drain oil from the gearbox.

5. Remove the four screws attaching the gearbox cover to the

gear housing and remove the gearbox cover.

6. Inspect gears for broken or severely worn teeth and inspect

all bearings. Replace as necessary. The overload slip clutch

is factory calibrated and must not be disassembled or

readjusted.

7. Reassemble in reverse order of disassembly making sure

the gasket is in place and in good condition. Coat gasket

with Permatex

®

or other gasket cement. Extreme care should

be taken to avoid damage to oil seals.

8. Check all wire terminals to be sure they are properly seated

and in accordance with wiring diagram. Before placing

lifting motor back into service, check brake adjustment.

Failure to follow proper lockout/tagout procedures may

present the danger of electrical shock.

TO AVOID INJURY:

Disconnect power and lockout/tagout disconnecting

means before removing cover or servicing this

equipment.

Do not disassemble or readjust clutch, or replace with

a clutch assembly from another lifting motor. Doing so

will void the warranty and may create an unsafe

condition. If replacement is needed due to wear or

loss of adjustment, always use a new clutch assembly.

Country Club Road

P.O. Box 779

Wadesboro, NC 28170 USA

TEL: (800) 477-5003

FAX: (800) 374-6853

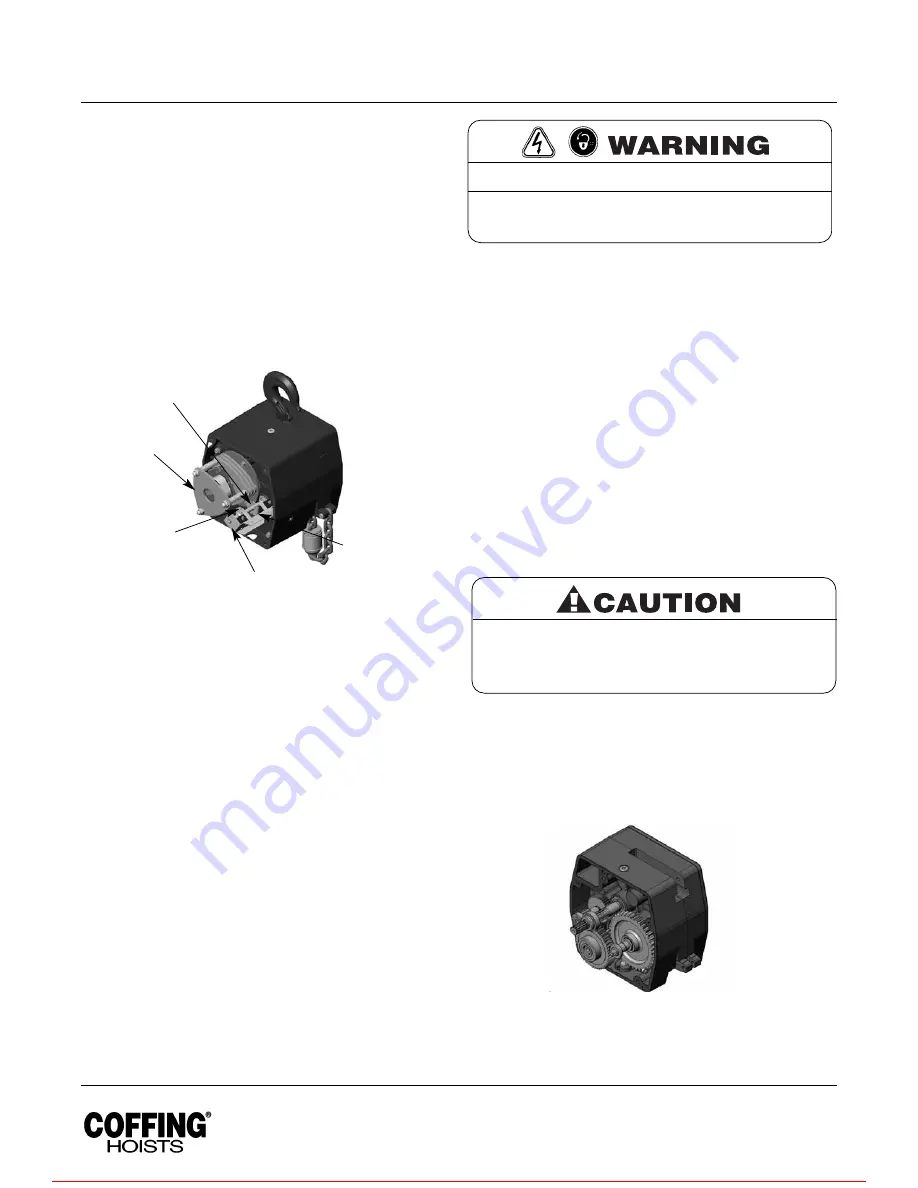

Figure 5 — Brake and Limit Switch Assembly

Spring

Guide

Plate

Silver Nut

(Down)

Gold Nut

(Up)

Brake

Assembly

Limit Switch

Assembly

Figure 6 - Assembled Gearing

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com