16

EC3-680-3 February 2017

Order # 5041558-0 & 5041679-0

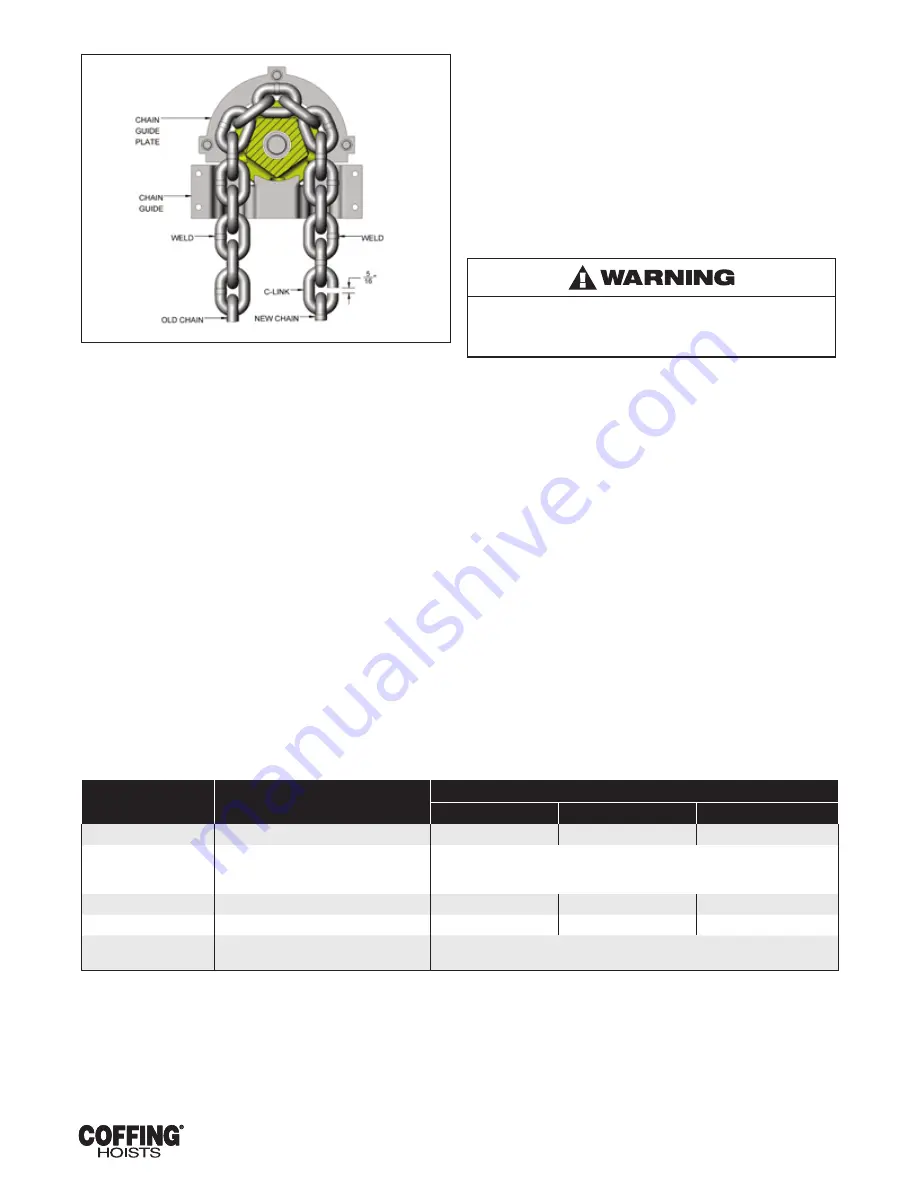

FIGURE 5-4. CHAINING HOIST

j. Remove both the "C" link and the old chain from the slack

end pin (No. 13, Figure 8-6). This can be accomplished by

depressing the pin against the slack end spring (14) with a

small screwdriver. Depress the slack end pin and install the new

chain observing proper orientation of the slack end of the chain

when secured. .Avoid twists in the chain.

k. Adjust the lower limit switch per paragraph 5-2.b.

l. Attach the bottom hook on single-chained hoists to the loose

end of the chain. On double-chained hoists, feed the loose end

of the chain through the load block (welds of the upstanding

links will be in towards the sheave) and fasten the end of the

chain to the dead end pin (No. 31, Figure 8-6B). On triple chain

hoists, feed the loose end of the chain through the load block

(welds toward sheave), around the idler sheave in the hoist, and

to the center of the load block.

m. Adjust the upper limit switch per paragraph 5-2.a (No. 30,

Figure 8-6C)

n. Lubricate the new chain per paragraph 5-6.a and perform an

operation test of the hoist.

5-6. LUBRICATION

Proper lubrication is necessary for long, trouble-free hoist operation.

Refer to the following and to Table 5-1, Recommended Lubrication

Schedule, for lubrication points, type of lubricant, and frequency of

lubrication.

a. Load Chain. Clean the load chain with a non-acid and non

caustic solvent and coat with SAE 90 gear oil. Wipe excess

oil to prevent dripping. If the hoist is used in an atmosphere

containing abrasive dust, the chain should be cleaned and oiled

more frequently. Never apply grease to the chain.

b. Gearing. The gear case of the hoist is filled at assembly with

1 gal. of a gear oil containing special friction-reducing additives.

The use of gear oils other than that recommended in Table

5-1 can cause brake chatter or can render the load brake

incapable of holding a load. A 1 gal. container of this oil is

available from Coffing (Part No. 14J11).

c. To check the oil level, remove the 1/4" pipe plug from the

side of the hoist. With the hoist hanging level, transmission oil

should be even with the edge of the tapped plug hole.

d. The length of time between necessary oil changes will depend

on the severity of use the hoist receives. In general, the oil

should be changed every 12 months of normal operation, or

every 200 hours of actual hoist on-time. Very heavy use or

operation in high ambient temperatures (over 105°F) will require

that oil be changed more often. An indication of the need for oil

replacement is load brake noise. If an erratic tapping sound is

made when lowering a load, the oil should be changed.

e. Limit Switch Shaft. To prevent rust, the threaded limit switch

shaft should be given a light coat of grease or sprayed with a

general purpose lubricant.

f. Idler Sheave Bearing (double and triple chain models only).

Use a grease gun to put about a teaspoon of grease through

the grease fining in the bottom block shaft. Avoid pumping an

excessive amount of grease into the bottom block. On triple

chain hoists, use a grease gun to lubricate the idler sheave in

the hoist until fresh grease pumps from the ends of the sheave.

g. Hook Bearing. Apply a few drops of SAE 30 oil around the edge

of the bearing.

TABLE 5-1. RECOMMENDED LUBRICATION SCHEDULE MODEL EC ELECTRIC CHAIN HOIST

Component

Type of Lubricant

Type of Service and Frequency of Lubrication

Heavy

Normal

Infrequent

Load Chain

SAE 90 Gear Oil

Daily

Weekly

Monthly

Gearing

Coffing No. H-7813 transmission oil ( Kit No.

14J11 contains quantity of oil sufficient for one

oil change)

At periodic inspection (See Figure 4-1, paragraph 5-6-B)

Limit Switch Shaft

“WD-40” or general purpose spray lubricant

Monthly

Yearly

Yearly

Load Hook Bearing

SAE 30 Gear or Motor Oil

Weekly

Monthly

Yearly

Idler Sheave Bearing

(Bushing)

NLGI #2 multi-purpose lithium base grease

(Coffing No. H-7610)

At periodic inspection (See Figure 4-1)

NOTE: All bearings except hook and idler sheave bearings are prelubricated and sealed.

* This lubrication schedule is based on a hoist operating in normal environmental conditions. Hoists operating in adverse atmospheres containing excessive heat, corrosive fumes or vapors,

abrasive dust, etc., should he lubricated more frequently.