7

Country Club Road

P.O. Box 779

Wadesboro, NC 28170 USA

TEL: (800) 477-5003

FAX: (800) 374-6853

HOOKS

Refer to Figure 2.

1. Inspect hooks once daily for cracking, extreme wear or

spreading. Replace hooks showing any of these signs. If the

throat openings are spread wider than the maximum

permissible 15% increase listed here, the hooks have been

overstressed and must be replaced. Any hook that is bent or

twisted more than 10 degrees from the plane of an unbent

hook must also be replaced.

2. The hook latches should be inspected to ensure that they

close the hook throat opening in a secure manner when a

load is applied. Inspect the hook shank and nut for any

stripping of the threads or other damage. The hook nut

should be fully restrained by the retaining pin.

3. In addition to above, load hooks should be inspected for

cracks by the magnetic particle, dye penetrant or other

suitable crack testing inspection method. This should be

done at least once a year.

1 Ton & Under

1

11

/

32

"

1

7

/

32

"

2 ton

1

11

/

32

"

1

11

/

32

"

(*) Maximum permissible throat opening of hook.

CHAIN

Chain is to be kept clean and lubricated (See LUBRICATION,

page 9). Visually check chain every time hoist is used. Hoist

must not be operated when chain is twisted or kinked. An

important phase of hoist maintenance is chain inspection.

Check individual links and check for chain elongation.

1. Check the chain for overall wear or stretch by selecting an

unworn, unstretched length of chain (at the slack end for

example). Let the chain hang vertically with a light load

(about 20 pounds) on the chain to pull it taut. Use a large

caliper to measure the outside length of a convenient

number of links (about 12 inches). Measure the same

number of links in a used section of chain and calculate the

percentage increase in length of the worn chain.

2. If the length of the worn chain is more than 1½% longer than

the unused chain (0.015" per inch of chain measured), then

the chain should be replaced. If the chain is worn less

than 1½%, check it at several more places along its length. If

any section is worn more than 1½%, the chain should

be replaced.

Chain Replacement with Chain in Hoist

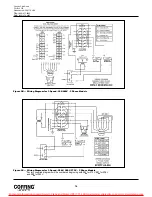

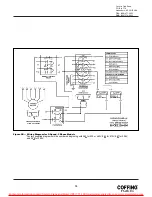

Refer to Figures 3 & 4.

1. Run hook up to its top limit.

2. DISCONNECT HOIST FROM POWER SUPPLY and

remove the electrical cover.

3. Using a screwdriver, pry the spring guide plate out of the

slots in the limit switch nuts (See Figure 3). Turn the gold

nut back to about the center of the threaded screw. Do not

disconnect the wires from the limit switches.

4. Remove the load block assembly from the old chain. On

double-chained hoists detach the chain from the chain

support and pull it through the load block assembly (See

Figure 4).

5. Make a “C” shaped chain link by grinding through the end

link on the load end of the old chain.

6. Using the “C” link, attach the new chain to the load end of

the old chain. Be sure that the welds of the upstanding links

of the new chain will face outward from the load sheave.

The end links must be oriented for attachment to the dead-

end screw and the chain support (double-chained only)

without any twist in the chain.

7. With the electrical cover off, connect the hoist to the power

supply. Be sure that the green ground wire is properly

grounded (See INSTALLATION, page 4).

8. Carefully jog the “UP” button and run the joined pieces of

chain into the hoist until about 15" of the new chain comes

out the other side.

9. DISCONNECT HOIST FROM POWER SUPPLY.

10. Remove the “C” link and the old chain. Remove the chain

stop by prying off its retaining ring with a flathead

screwdriver. If attached, remove the old chain from the

chain stripper by removing the retainer clip and

attachment pin.

11. Attach the chain stop to the slack end of the new chain by

capturing the 12th link with the two stop halves positioned

with their tapered ends pointing towards the hoist. Slide the

sleeve over the halves and attach the retaining ring. If you

are not using a chain container, attach the slack end of the

new chain to the side of the hoist using the attachment pin

and retainer clip. DO NOT allow twists in the chain.

12. Adjust the lower limit switch (See ADJUSTING LOWER

LIMIT, page 8).

Figure 3 — Limit Switch Assembly

“

“X

X”

” D

Diim

me

en

ns

siio

on

n*

*

H

Ho

oiis

stt

T

To

op

p

B

Bo

otttto

om

m

C

Ca

ap

pa

ac

ciitty

y

H

Ho

oo

ok

k

H

Ho

oo

ok

k

The chain used on this hoist has very carefully

controlled dimensions and has been heat treated. Do

not attempt to substitute other manufacturer’s chain.

X

Figure 2 — Hook

Inspection

Spring

Guide

Plate

Silver Nut

(Down)

Gold Nut

(Up)

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com