9

Johanna

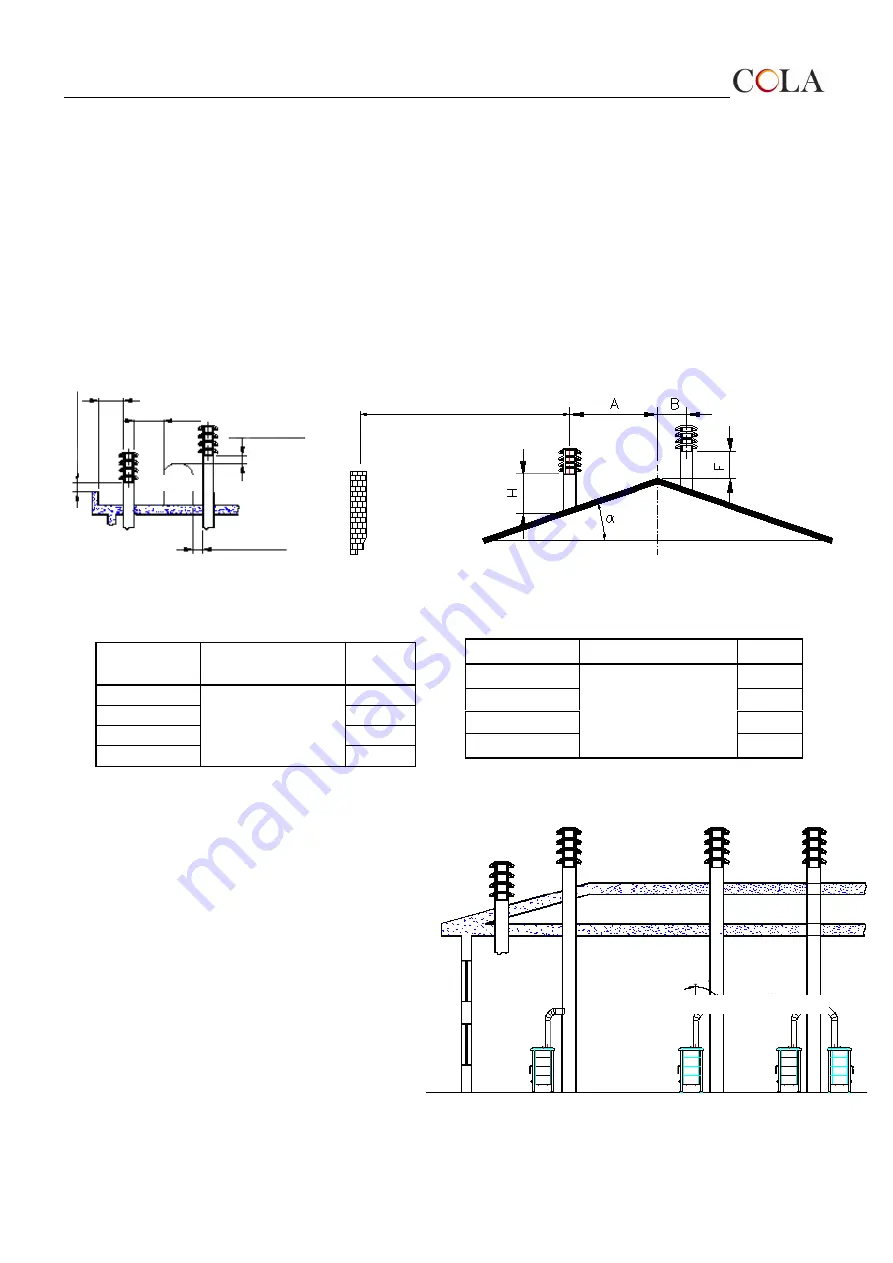

Roof

slope

(α)

(α)

(α)

(α)

Distance A

H

15°

1.00 m

30°

1.30 m

45°

2.00 m

60°

More than 1.85 m

2.60 m

If the air is insufficient, even the operation of an extractor hood in the room or exhaust fans can negatively affect stove

operation.

2.5 Advice on flues and connections

Flues must be made from suitable materials and perfectly insulated, with characteristics that prevent temperature

decreases.

The inner walls must be perfectly smooth without any narrowing or protrusions along the entire length, so as not to

create friction or vortices in the smoke which could cause a considerable reduction in draught.

Any cleaning and inspection doors must be perfectly closed during operation.

The flue outlets must be 0.5 m higher than any obstacles located less than 10 m away and must end with chimney caps

or cowls having a useful outlet cross section of at least double that of the flue.

The following two figures give the data regarding the distances and positioning of chimney caps in conformity with the

provisions of UNI 10683/98.

ostacolo

Inferiore di 5 m

M

in

0

.5

m

Min 0.5m

circa 0.5m

Min 0.5m

La bocca del camino deve essere di almeno

0.5m dalla sommità di un ostacolo se questi

si trova ad una distanza inferiore ai 10m

fig 3 Chimney cap positioning and distances

UNI 10683/98 tables

Before connecting a heating stove to an existing chimney, in addition to complying with that described above, make

sure there are no openings or cracks where air could enter and cause a temperature decrease affecting the draught.

Also make sure there are no hindrances caused by

foreign bodies or a build-up of soot.

The first connection section leaving the stove

should be vertical, whereas the flue connection to

the chimney (which goes to the chimney cap) must

only enter by a few cm, so as not to reduce the

cross section of the flue.If the flue is not

perpendicular to the chimney it is advisable to

make the connection with

special steel fittings that allow a maximum slope of

45°.

If the walls and ceiling are made of flammable

materials, the parts in contact with the flue must be

suitably insulated. All connection joints must be

carefully sealed, in particular where the connection

enters the flue.

If there are several heating stoves in the same

home, each must have its own flue. It is inadvisable

to make openings in the flue for other appliances, since the draught could be negatively affected.

Roof slope

(α)

(α)

(α)

(α)

Distance B

H

15°

0.50 m

30°

0.50 m

45°

0.50 m

60°

Less than 1.85 m

0.50 m

NO

NO

SI

MAX 45°

Fig.4 Stove-chimney connection